包装机械产业运营平台开发公司

Title: The Development of a Packaging Machinery Industry Operation Platform

Introduction:

In today's fast-paced and ever-evolving world, the packaging industry plays a crucial role in ensuring safety, convenience, and efficiency in the delivery of products. Behind this industry's success lies cutting-edge technology, particularly in the form of packaging machinery. However, with the rapid growth of this sector, the need for a comprehensive and efficient operation platform has become increasingly apparent. In response to this demand, our company has embarked on the development of a packaging machinery industry operation platform.

I. The Need for an Operation Platform:

The packaging machinery industry is characterized by a diverse range of manufacturers, suppliers, and customers. Each entity operates within its own unique set of requirements, practices, and technological capabilities. As a result, communication and coordination between these entities can be challenging, leading to inefficiencies, delays, and increased costs. An operation platform will provide a centralized hub for all stakeholders, streamlining processes to improve productivity and enhance the overall supply chain.

II. Benefits of the Operation Platform:

1. Enhanced Communication: The operation platform will facilitate effective communication between manufacturers, suppliers, and customers. Through real-time messaging, forums, and discussion boards, stakeholders can exchange vital information, address concerns, and collaborate on projects more efficiently.

2. Digitalized Procurement and Inventory Management: The platform will integrate procurement functions, allowing manufacturers to source materials and spare parts seamlessly. Furthermore, it will provide precise inventory management tools, reducing wasted resources and enabling companies to respond swiftly to market demands.

3. Data Analytics and Predictive Maintenance: By collecting and analyzing data from machinery sensors, the platform can identify patterns and trends, enabling predictive maintenance. This proactive approach minimizes downtime, reduces maintenance costs, and maximizes overall operational efficiency.

4. Standardization and Quality Control: The platform will establish standardized operating procedures, ensuring consistent quality across the industry. By adhering to these guidelines, manufacturers can reduce defects, improve customer satisfaction, and build a reputation for reliability.

5. Resource Optimization: The operation platform will allow for the optimization of resources such as energy, materials, and labor. Through data-driven insights, manufacturers can identify areas for improvement, leading to cost savings and a more sustainable approach to production.

III. Challenges and Solutions:

Developing a comprehensive operation platform for the packaging machinery industry presents its own set of challenges. These include data security, compatibility issues, and industry-wide adoption. To overcome these obstacles, our company has implemented robust security measures, ensured compatibility across various software and hardware systems, and is actively collaborating with industry stakeholders to drive widespread adoption.

Conclusion:

The development of a packaging machinery industry operation platform holds immense potential to transform the way this sector operates. By centralizing communication, streamlining processes, and facilitating collaboration, the platform will boost productivity, reduce costs, and promote innovation. Our company remains committed to delivering a cutting-edge solution that empowers manufacturers, suppliers, and customers alike in this dynamic and essential industry.

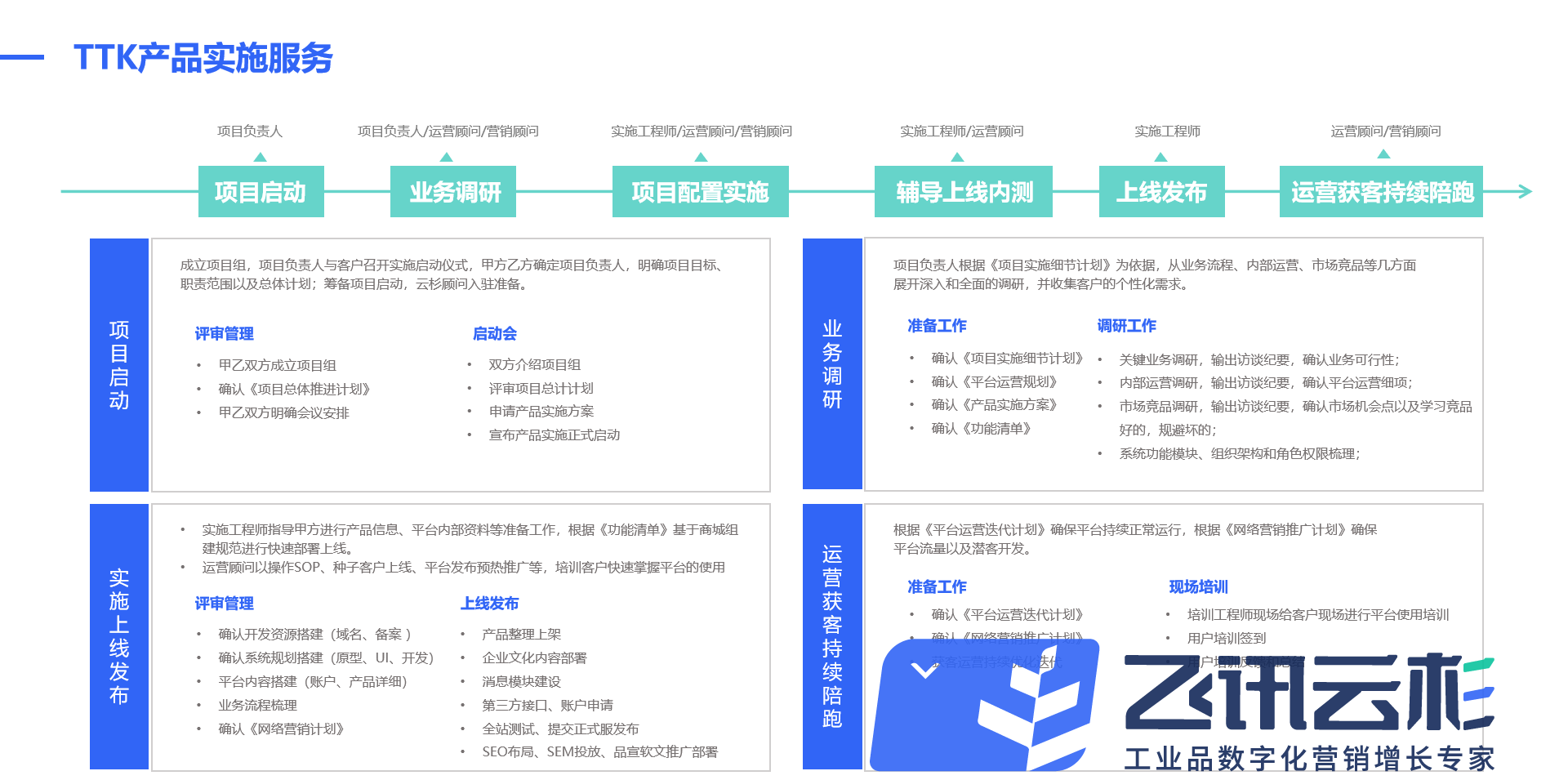

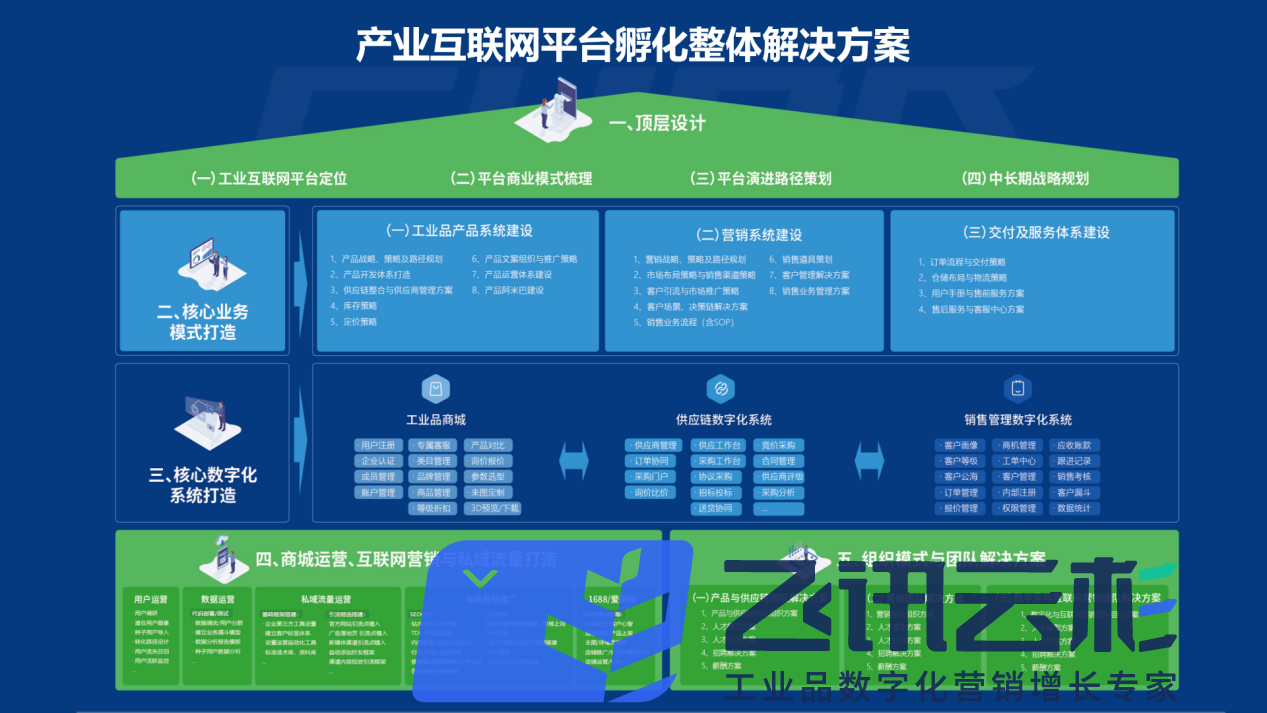

飞讯云杉是一家提供全链数字化营销解决方案的企业,聚焦产业互联网平台孵化服务,为工业制造企业搭建数字化营销-数字化供应链-业务智能决策全链数字化营销业务体系,实现工业品营销模式的创新,通过数字化赋能销售快速复制,让每一个工业品制造企业都拥有全链数字化营销业务体系。

请先 登录后发表评论 ~