喷涂设备工业互联网平台打造

Title: Building an Industrial Internet Platform for Spray Coating Equipment

Introduction

In recent years, with the rapid development of technology and the increasing demands for environmental protection and efficiency improvement, spray coating equipment has become widely used in various industries. To meet the growing needs of industrial production, it is crucial to establish a comprehensive industrial internet platform specifically designed for spray coating equipment. This article aims to explore the benefits and challenges of such a platform and discuss its potential impact on the industry.

The Importance of an Industrial Internet Platform

An industrial internet platform for spray coating equipment can revolutionize the way businesses operate. By connecting different devices, systems, and processes, it enables real-time monitoring, data analysis, and remote control. This not only enhances operational efficiency but also reduces maintenance costs and improves the overall quality of products.

Benefits of the Platform

1. Real-time Monitoring: With the platform, operators can monitor the operation status and parameters of spray coating equipment in real-time. This allows for efficient troubleshooting and preventive maintenance, minimizing downtime and improving productivity.

2. Data Analysis and Optimization: The platform collects data from various sources, such as production lines, sensors, and equipment, enabling advanced analytics. By analyzing this data, businesses can identify patterns, optimize processes, and make data-driven decisions to achieve higher quality and productivity.

3. Remote Control and Management: The platform enables remote control and management of spray coating equipment. Operators can adjust parameters, monitor performance, and even conduct virtual training sessions remotely. This reduces the need for onsite personnel and increases flexibility in managing multiple production sites.

4. Predictive Maintenance: Through constant monitoring and data analysis, the platform can detect potential equipment failures in advance. By implementing predictive maintenance strategies, businesses can reduce unexpected breakdowns, optimize maintenance schedules, and extend the lifespan of their equipment.

Challenges and Solutions

1. Data Security: As spray coating equipment handles sensitive data, data security is a paramount concern. The platform should incorporate robust encryption measures, implement strict access controls, and regularly update security protocols to protect against cyber threats.

2. Interoperability: Spray coating equipment is often manufactured by different vendors with varying connectivity standards. The platform should support open protocols and ensure seamless integration between different devices and systems. Standardization efforts should be encouraged to promote compatibility across the industry.

3. Skill Development: The increased reliance on digital technologies requires the workforce to acquire new skills. Training programs and workshops should be provided to professionals in the spray coating industry to enhance their understanding of the platform and its applications.

4. Scalability: As businesses grow and adopt more spray coating equipment, the platform must be scalable to accommodate the increasing number of devices and data. Continuous technological advancements and flexible infrastructure design are necessary to meet future demands.

Conclusion

The establishment of an industrial internet platform specifically tailored for spray coating equipment holds immense potential for revolutionizing industrial operations. By leveraging real-time monitoring, data analysis, remote control, and predictive maintenance, businesses can achieve higher efficiency, improved quality, and reduced costs. However, the successful implementation of such a platform requires addressing challenges related to data security, interoperability, skill development, and scalability. With careful planning and collaboration among industry stakeholders, the vision of a connected and intelligent spray coating industry can become a reality, unlocking new opportunities for growth and innovation.

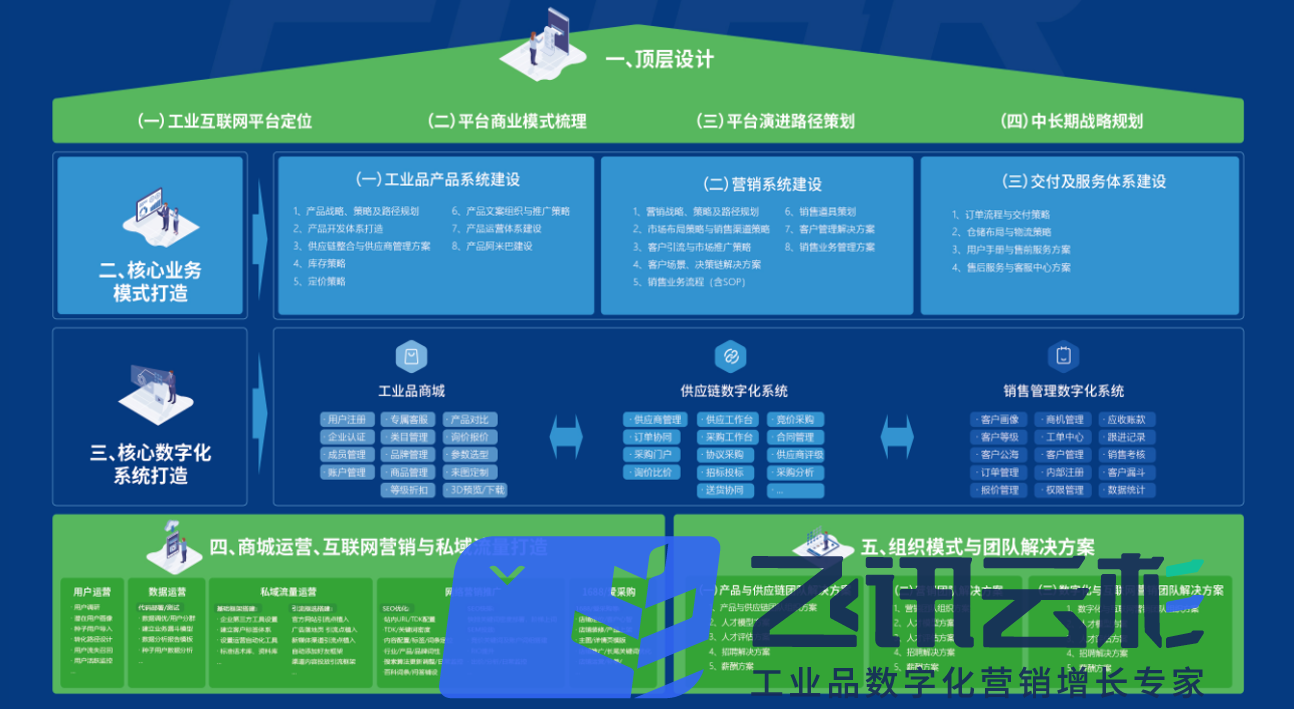

飞讯云杉是一家提供全链数字化营销解决方案的企业,聚焦产业互联网平台孵化服务,为工业制造企业搭建数字化营销-数字化供应链-业务智能决策全链数字化营销业务体系,实现工业品营销模式的创新,通过数字化赋能销售快速复制,让每一个工业品制造企业都拥有全链数字化营销业务体系。

请先 登录后发表评论 ~