气体检测与分析仪器工业互联网平台服务商

Title: Industrial Internet of Things (IIoT) Platform Services for Gas Detection and Analysis Instruments

Introduction:

In the realm of industrial safety and environmental monitoring, the utilization of gas detection and analysis instruments is paramount. These devices play a crucial role in detecting and analyzing gases to ensure the safety of personnel, prevent accidents, and maintain optimal working conditions. With the advent of the Industrial Internet of Things (IIoT), gas detection and analysis instrument manufacturers have embraced this technology to create powerful platforms that enhance their products' functionality, ease of use, and overall efficiency. This article will delve into the services offered by IIoT platform providers in the gas detection and analysis instrument industry.

1. Real-time Data Monitoring and Analytics:

IIoT platforms enable real-time data monitoring and analytics, allowing users to remotely access and visualize data from multiple gas detection and analysis instruments. This capability offers significant advantages, including:

a) Instantaneous Alert Notifications: IIoT platforms can send instant notifications to users when gas concentrations reach critical levels or exceed predefined thresholds. This feature enables quick response times, minimizing risks to personnel and ensuring timely preventive measures.

b) Trend Analysis: By collecting and analyzing historical data, IIoT platforms provide valuable insights into gas concentration trends. This information facilitates the identification of potential risks, source detection, and the formulation of appropriate long-term safety strategies.

c) Data Visualization: Through intuitive dashboards and interactive charts, IIoT platforms present gas concentration data in a comprehensive and user-friendly manner. This visual representation allows operators to quickly understand complex data and make informed decisions.

2. Remote Configuration and Calibration:

Traditional gas detection and analysis instruments often require manual configuration and calibration processes. However, IIoT platforms streamline these tasks by enabling remote access to instrument settings. Key benefits include:

a) Efficiency and Convenience: IIoT platforms allow users to remotely configure multiple instruments simultaneously, saving time and effort. Additionally, calibration processes can be automated, reducing the need for on-site technicians.

b) Standardization: IIoT platforms provide standardized configuration and calibration procedures, ensuring consistency across multiple devices. This standardization minimizes errors and improves the overall reliability of data collected by the instruments.

c) Regulatory Compliance: IIoT platforms offer features that assist users in meeting regulatory requirements. They facilitate the automatic generation of compliance reports, making it easier to demonstrate adherence to safety and environmental standards.

3. Predictive Maintenance and Asset Management:

IIoT platforms enable predictive maintenance and efficient asset management for gas detection and analysis instruments. This includes:

a) Condition Monitoring: IIoT platforms collect and analyze device-specific operating data, enabling the detection of anomalies or signs of impending malfunctions. By identifying potential issues before they lead to instrument failure, operators can proactively schedule maintenance activities, reducing downtime and improving operational efficiency.

b) Remote Diagnostics: IIoT platforms allow remote diagnostics by leveraging real-time instrument data. This capability facilitates troubleshooting, minimizing the need for on-site visits from technical support teams.

c) Inventory Management: IIoT platforms provide centralized inventory management, offering insights into the availability and condition of gas detection and analysis instruments. This helps optimize asset allocation, track instrument utilization, and plan replacements or upgrades efficiently.

Conclusion:

The Industrial Internet of Things (IIoT) has revolutionized the gas detection and analysis instrument industry, offering a range of services that enhance safety, efficiency, and operational effectiveness. Through real-time data monitoring, remote configuration, predictive maintenance, and asset management, IIoT platforms empower users to make informed decisions, ensure compliance with regulations, and ultimately create a safer working environment. As technology continues to advance, the role of IIoT in gas detection and analysis instruments will only become more integral, facilitating improved safety standards and greater operational efficiency.

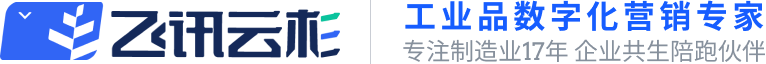

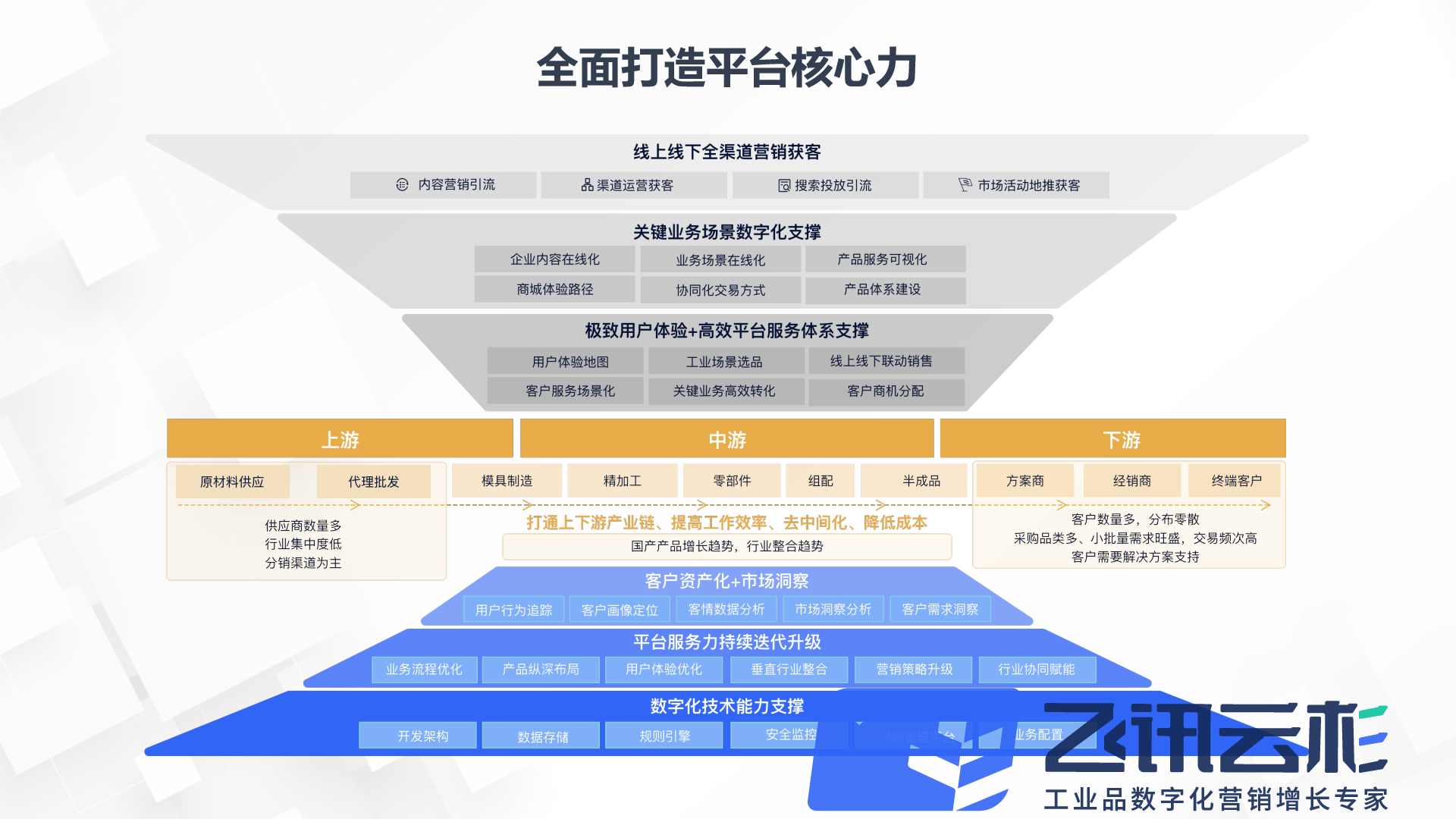

飞讯云杉是一家提供全链数字化营销解决方案的企业,聚焦产业互联网平台孵化服务,为工业制造企业搭建数字化营销-数字化供应链-业务智能决策全链数字化营销业务体系,实现工业品营销模式的创新,通过数字化赋能销售快速复制,让每一个工业品制造企业都拥有全链数字化营销业务体系。

请先 登录后发表评论 ~