气压设备与气压元件工业互联网平台服务商

Title: Industrial Internet Platform Services for Pressure Equipment and Components

Introduction:

In recent years, with the rapid development of technology, the industrial internet has emerged as a powerful tool for transforming traditional industries. Among them, the field of pressure equipment and components has witnessed remarkable advancements. As a result, the emergence of industrial internet platform services in this sector has revolutionized the way businesses operate. In this article, we will explore the significance and impact of these services on the pressure equipment industry.

1. What are Industrial Internet Platform Services?

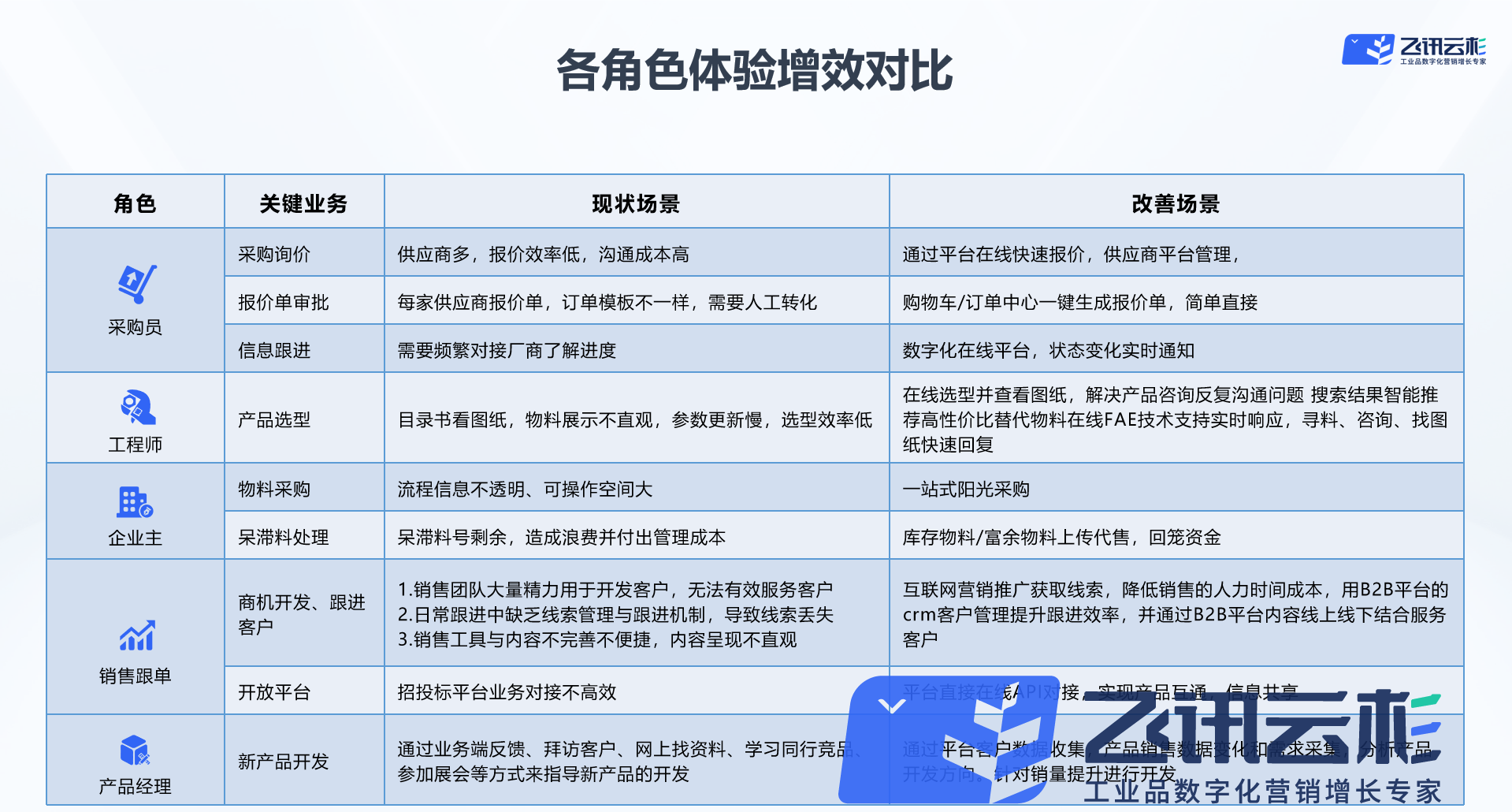

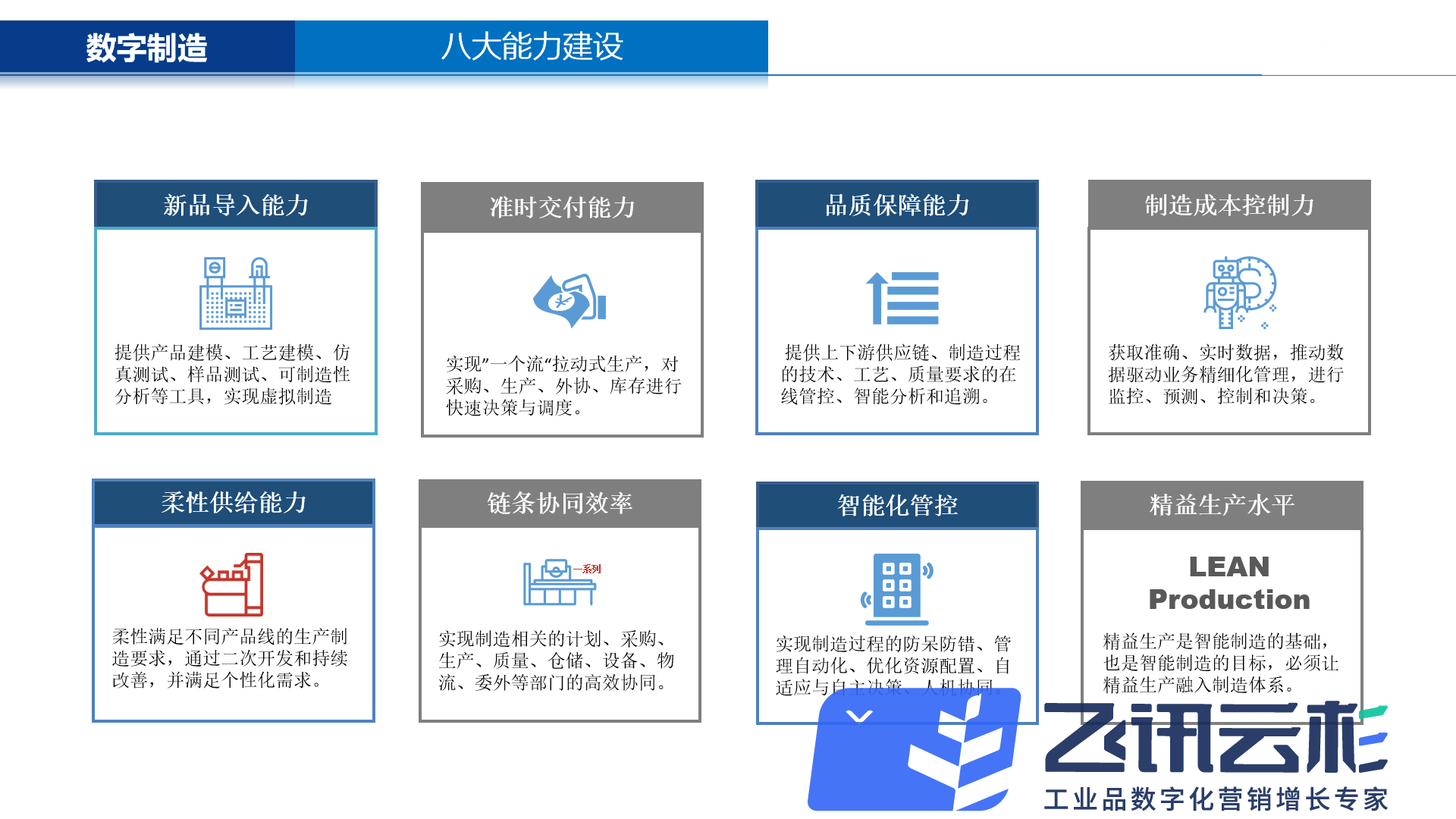

Industrial internet platform services refer to the integration of advanced technologies, such as cloud computing, big data analysis, and artificial intelligence, into the operation and management of pressure equipment and components. These services provide a digitalized platform that connects various stakeholders, including manufacturers, suppliers, and end-users, in a seamless and efficient manner.

2. Enhancing Operational Efficiency:

One of the key benefits of industrial internet platform services is the enhancement of operational efficiency. By leveraging analytical tools and real-time monitoring systems, manufacturers can gain valuable insights into the performance of their equipment. This enables proactive maintenance, minimizing downtime, and reducing costs associated with unscheduled repairs. Additionally, suppliers can optimize their inventory management, resulting in improved productivity and reduced lead times.

3. Facilitating Remote Monitoring and Control:

Industrial internet platforms enable remote monitoring and control of pressure equipment, regardless of geographic location. With the integration of IoT (Internet of Things) devices, real-time data regarding temperature, pressure, and other critical parameters can be collected and analyzed. This allows for prompt detection of anomalies and the implementation of necessary corrective measures, thereby ensuring the safe and reliable operation of industrial equipment.

4. Predictive Maintenance:

The ability to collect and analyze vast amounts of data through industrial internet platforms opens up new possibilities for predictive maintenance. By utilizing machine learning algorithms, historical data from pressure equipment can be processed to identify patterns and predict potential failures. This proactive approach to maintenance reduces the risk of unexpected breakdowns, increases the lifespan of equipment, and optimizes maintenance schedules.

5. Supply Chain Optimization:

Industrial internet platform services also play a crucial role in optimizing the supply chain for pressure equipment and components. By connecting manufacturers, suppliers, and end-users through a digitalized platform, these services facilitate the seamless exchange of information, ensuring accurate demand forecasting and efficient inventory management. This leads to reduced lead times, minimized costs, and improved customer satisfaction.

6. Enhanced Safety and Compliance:

Safety is paramount in the pressure equipment industry. Industrial internet platforms enable real-time monitoring of safety parameters, such as pressure levels, temperature, and leakage detection. Early detection of potential hazards allows for immediate actions to be taken, mitigating the risk of accidents. Furthermore, these platforms facilitate regulatory compliance by providing a centralized database for storing and managing relevant documentation and certifications.

Conclusion:

The advent of industrial internet platform services has transformed the pressure equipment and components industry, revolutionizing the way businesses operate and manage their operations. These services have significantly enhanced operational efficiency, facilitated remote monitoring and control, enabled predictive maintenance, optimized the supply chain, and improved safety and compliance. As technology continues to advance, it is expected that further innovations and enhancements will bring even more benefits to this sector, driving its continued growth and development.

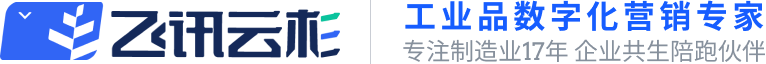

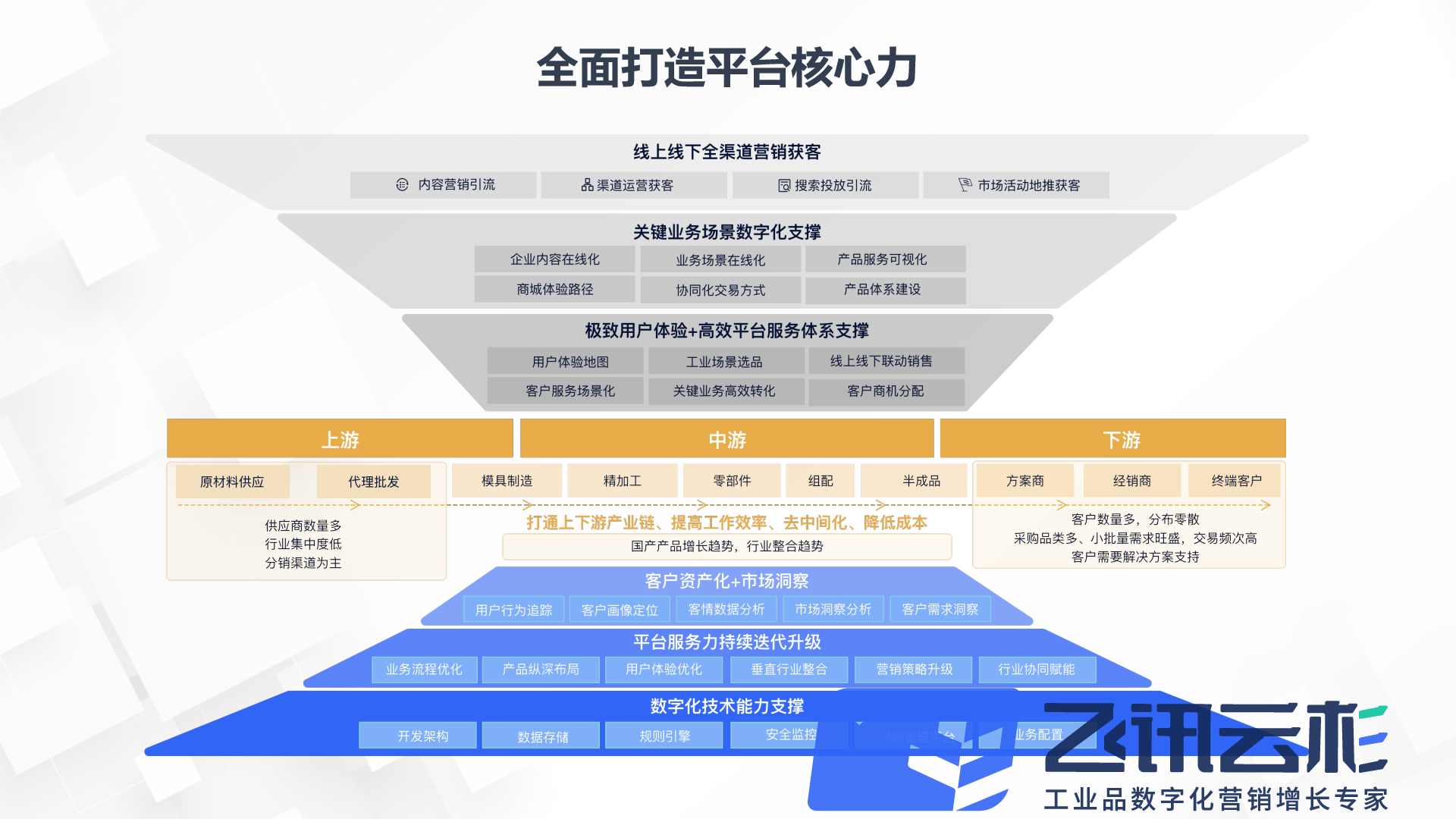

飞讯云杉是一家提供全链数字化营销解决方案的企业,聚焦产业互联网平台孵化服务,为工业制造企业搭建数字化营销-数字化供应链-业务智能决策全链数字化营销业务体系,实现工业品营销模式的创新,通过数字化赋能销售快速复制,让每一个工业品制造企业都拥有全链数字化营销业务体系。

请先 登录后发表评论 ~