质量控制与检测设备产业链平台系统搭建

Title: Building a Platform System for the Quality Control and Testing Equipment Industry Chain

Introduction:

In today's rapidly evolving market, the quality control and testing equipment industry plays a vital role in ensuring product excellence and consumer safety. To effectively manage and optimize this industry, a comprehensive platform system for the quality control and testing equipment industry chain is necessary. This article will explore the key aspects and benefits of such a platform system.

1. Integration of the Supply Chain:

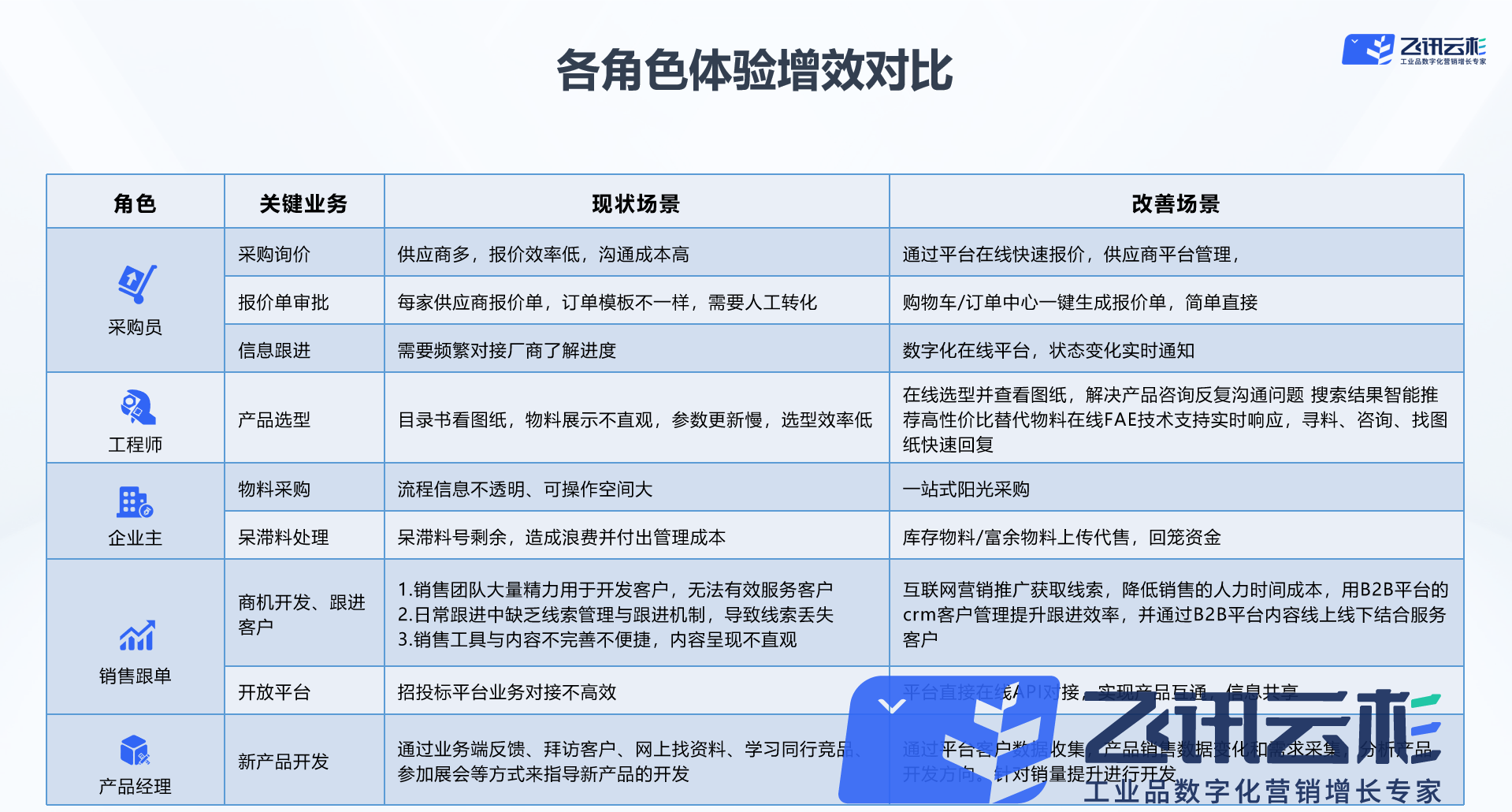

A platform system for the quality control and testing equipment industry chain aims to integrate various stakeholders, including manufacturers, suppliers, distributors, and customers. By connecting these entities, the system enables seamless collaboration, real-time data sharing, and efficient communication across the supply chain. This integration streamlines production processes, minimizes delays, reduces costs, and ensures timely delivery of high-quality equipment.

2. Enhanced Data Management:

Data is at the core of any quality control and testing equipment industry. A robust platform system allows for centralized data storage, analysis, and management. This centralized approach eliminates data silos and allows stakeholders to access critical information effortlessly. Through advanced analytics and reporting tools, the system provides valuable insights into performance metrics, quality trends, and market demands. This data-driven decision-making empowers businesses to proactively address challenges, optimize operations, and enhance competitiveness.

3. Standardization and Compliance:

Ensuring adherence to industry standards and regulations is crucial for the quality control and testing equipment industry. The platform system can incorporate standardized protocols and guidelines, facilitating compliance for manufacturers and ensuring the safety and reliability of equipment. By integrating quality control measures into the system, potential flaws and risks can be identified early on, reducing the likelihood of defects and recalls. This promotes customer trust, brand reputation, and overall industry growth.

4. Innovation and Collaboration:

The platform system serves as a catalyst for industry innovation and collaboration. It allows manufacturers, researchers, and other stakeholders to share knowledge, expertise, and ideas. Collaboration can lead to the development of advanced testing methods, technological breakthroughs, and improved equipment designs. Additionally, the platform system can facilitate resource pooling, enabling smaller businesses to access cutting-edge technologies and expertise that may otherwise be economically unfeasible.

5. Customer Satisfaction:

The ultimate goal of the quality control and testing equipment industry is to ensure customer satisfaction. The platform system enhances customer experience by providing transparency, reliability, and efficiency throughout the product lifecycle. Customers have access to comprehensive information on product specifications, certifications, and test results. This system also promotes effective communication between customers and manufacturers, allowing for feedback, inquiries, and timely support. By actively involving customers in the quality control process, the industry can adapt to their evolving needs, resulting in improved products and services.

Conclusion:

A platform system for the quality control and testing equipment industry chain brings numerous benefits to all stakeholders involved. From supply chain integration to enhanced data management, standardization, innovation, and customer satisfaction, the system optimizes operations, drives growth, and ensures high-quality products. Embracing such a platform system will enable the industry to stay competitive, adapt to market dynamics, and meet the ever-increasing demands for quality control and testing.

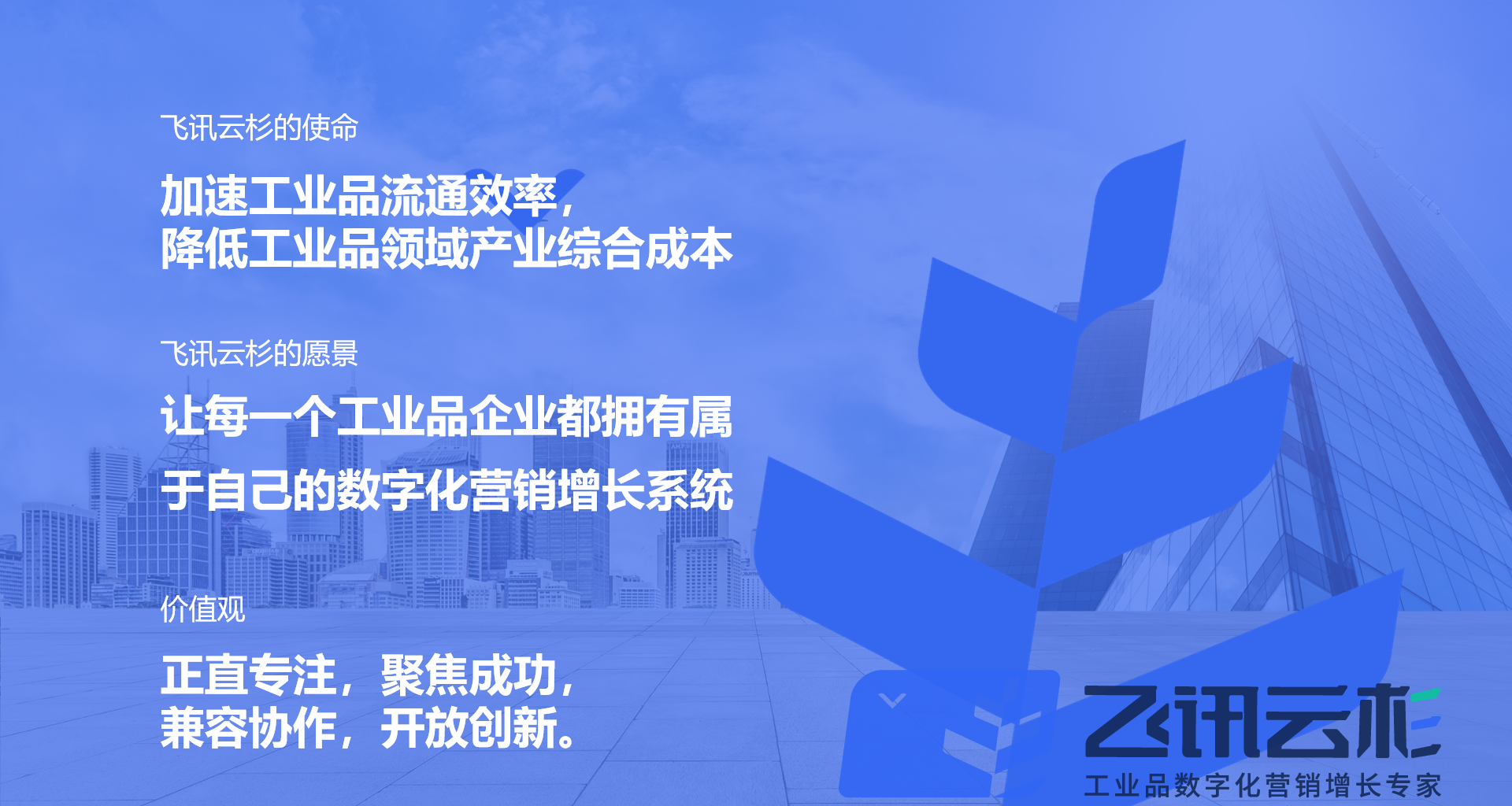

飞讯云杉是一家提供全链数字化营销解决方案的企业,聚焦产业互联网平台孵化服务,为工业制造企业搭建数字化营销-数字化供应链-业务智能决策全链数字化营销业务体系,实现工业品营销模式的创新,通过数字化赋能销售快速复制,让每一个工业品制造企业都拥有全链数字化营销业务体系。

请先 登录后发表评论 ~