工业阀门管道配件工业互联网平台打造

Title: Building an Industrial Internet Platform for Industrial Valve and Pipe Fittings

Introduction:

In the era of rapid technological advancement, industries worldwide are embracing the concept of the Industrial Internet. This powerful integration of machinery, data, and analytics has led to improved efficiency, productivity, and profitability. In this article, we will explore the significance of establishing an industrial internet platform specifically tailored for the valve and pipe fittings industry.

1. The Need for an Industrial Internet Platform:

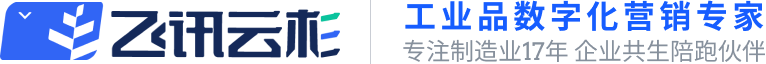

The valve and pipe fittings industry plays a vital role in numerous sectors, including oil and gas, chemical processing, power generation, and water treatment. These industries heavily rely on the precise control and safe transportation of fluids. An industrial internet platform can address critical challenges faced by manufacturers, suppliers, and end-users in this sector.

2. Streamlining Supply Chain Management:

An industrial internet platform provides a centralized hub where manufacturers, suppliers, and distributors can connect and collaborate seamlessly. By integrating supply chain management systems into a single platform, it becomes easier to monitor inventory levels, track orders, and manage logistics. Real-time data sharing enables quick decision-making, reduces lead times, and ensures on-time delivery.

3. Enhanced Product Quality and Safety:

The industrial internet platform allows for real-time monitoring of valve and pipe fitting performance through sensors and connected devices. Manufacturers can collect and analyze data on factors like pressure, temperature, and flow rate, enabling predictive maintenance and identifying potential issues before they cause failures. This results in improved product quality and safety, reducing downtime and costly repairs.

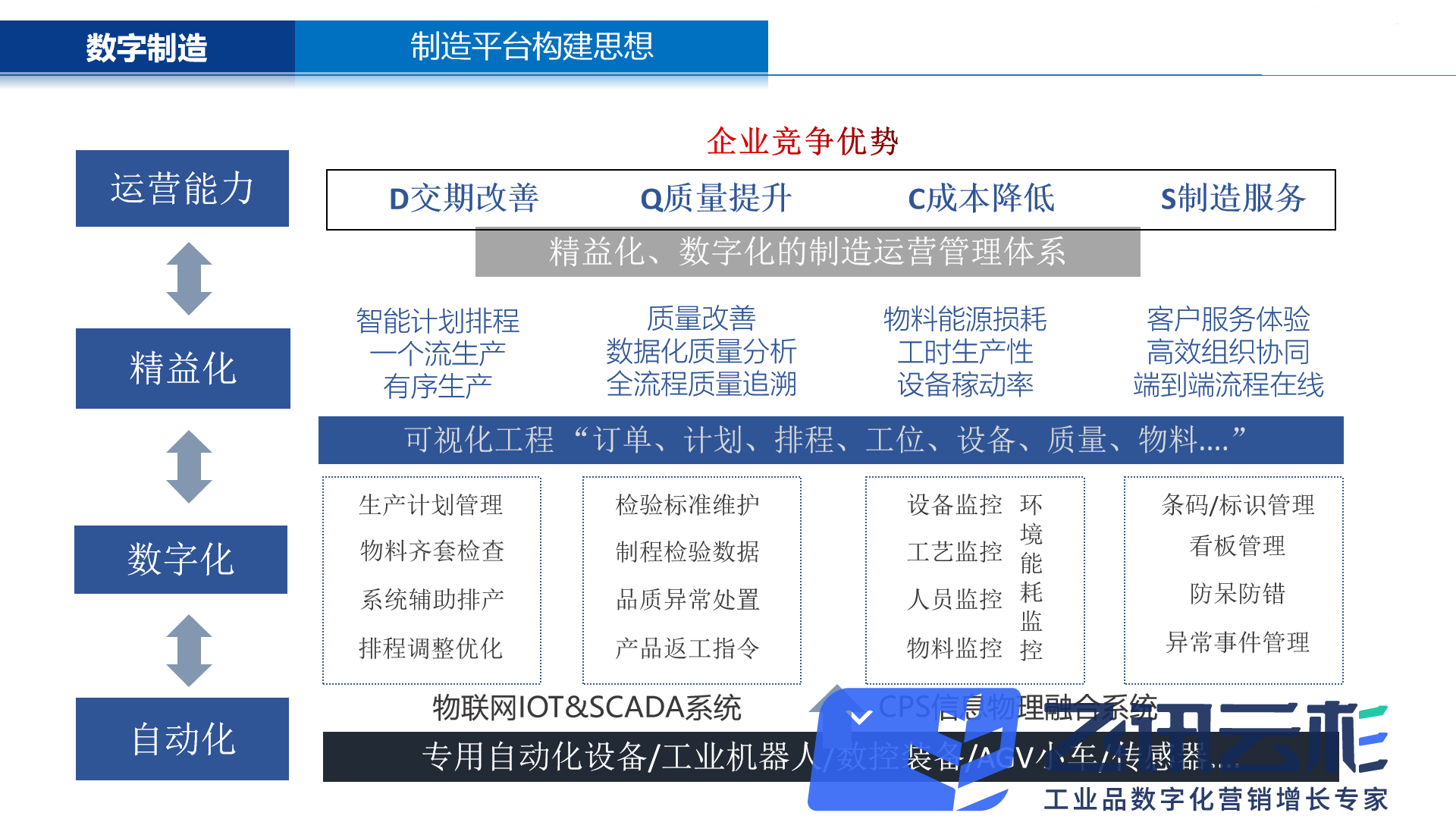

4. Intelligent Manufacturing and Automation:

Internet of Things (IoT) technologies can be integrated into valve and pipe fitting manufacturing processes, transforming traditional plants into smart factories. Industrial internet platforms enable the monitoring and control of production lines, optimizing energy consumption, reducing waste, and enhancing overall operational efficiency. Smart automation ensures consistent product quality while minimizing manual interventions.

5. Data-Driven Decision Making:

Data analytics and machine learning algorithms form the backbone of industrial internet platforms. By collecting and analyzing vast amounts of data, valuable insights can be gained, leading to informed decision-making. For example, manufacturers can optimize production schedules based on demand forecasts, suppliers can identify potential bottlenecks in the supply chain, and end-users can track and monitor valve performance remotely.

6. Remote Monitoring and Maintenance:

Traditionally, maintenance of valves and pipe fittings required physical inspections, often leading to unplanned downtime. With an industrial internet platform, remote monitoring and predictive maintenance become possible. Real-time data on valve health and performance allow for condition-based maintenance, minimizing downtime and maximizing asset utilization. This cost-effective approach saves time and resources for all stakeholders.

Conclusion:

The establishment of an industrial internet platform specifically designed for the valve and pipe fittings industry brings numerous benefits to manufacturers, suppliers, and end-users. Streamlined supply chain management, enhanced product quality and safety, intelligent manufacturing and automation, data-driven decision-making, and remote monitoring and maintenance are just a few advantages offered by such a platform. Embracing this technological revolution will undoubtedly lead to increased efficiency, productivity, and competitiveness in the industry.

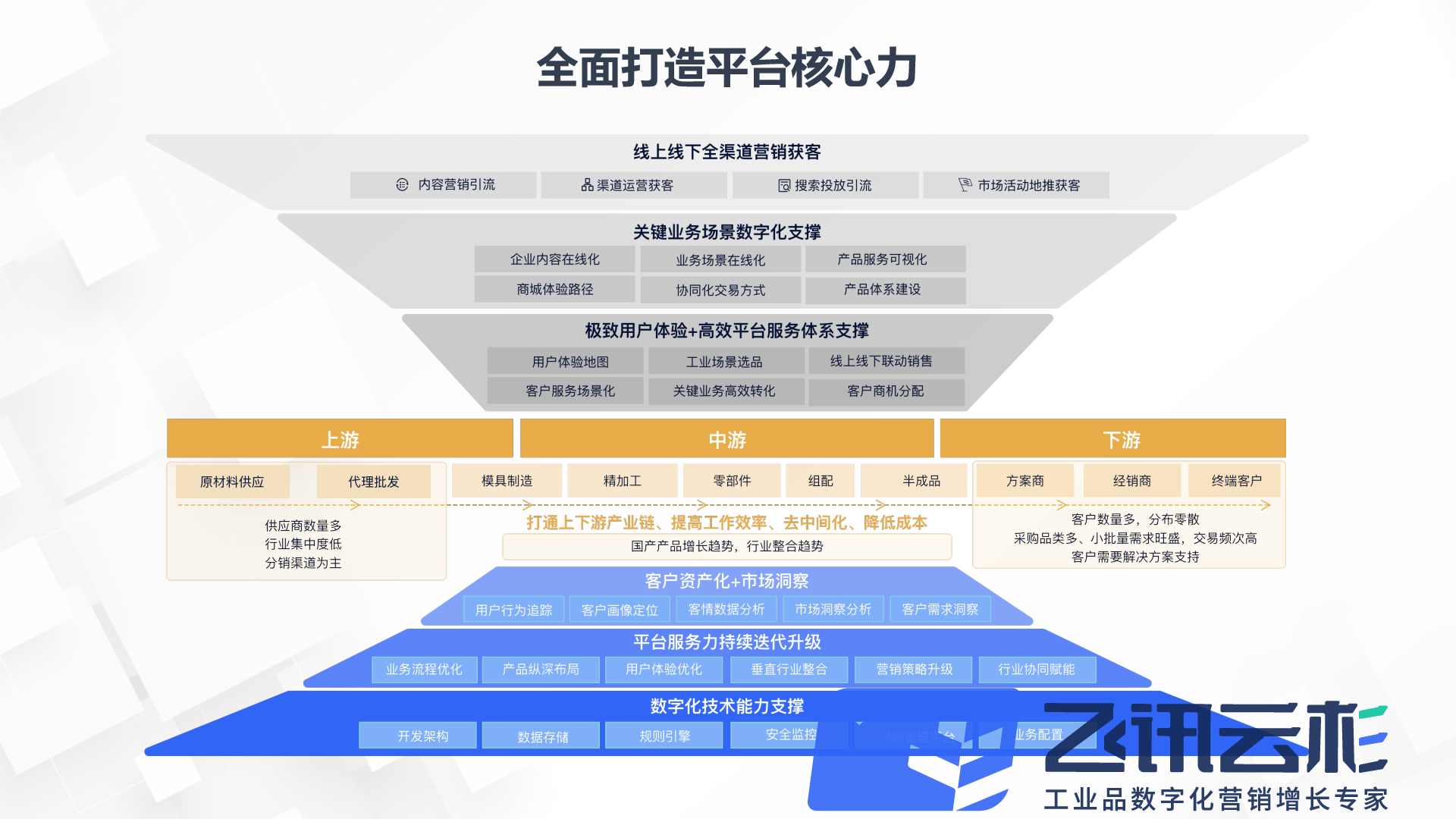

飞讯云杉是一家提供全链数字化营销解决方案的企业,聚焦产业互联网平台孵化服务,为工业制造企业搭建数字化营销-数字化供应链-业务智能决策全链数字化营销业务体系,实现工业品营销模式的创新,通过数字化赋能销售快速复制,让每一个工业品制造企业都拥有全链数字化营销业务体系。

请先 登录后发表评论 ~