电弧切割设备产业互联网平台服务商

Title: Empowering the Arc Cutting Equipment Industry through the Internet of Things

Introduction

In recent years, the Arc Cutting Equipment industry has witnessed a significant transformation with the advent of the Internet of Things (IoT). As the world becomes increasingly interconnected, businesses must adapt to remain competitive. This article explores the role of IoT in revolutionizing the Arc Cutting Equipment industry and the benefits it brings for both manufacturers and end-users.

1. Enhanced Efficiency and Precision

Traditionally, operating arc cutting equipment required manual intervention and constant monitoring. However, with IoT integration, these machines can now gather real-time data and make adjustments automatically. Sensors placed strategically on the equipment collect valuable information such as temperature, power usage, and gas levels, enabling accurate measurements and increasing efficiency. Manufacturers can identify and rectify issues promptly, reducing downtime and improving overall productivity.

2. Predictive Maintenance and Reduced Costs

Arc cutting equipment is subject to wear and tear over time, leading to unexpected breakdowns and costly repairs. With IoT-enabled sensors, manufacturers can monitor the health of their machines remotely. By analyzing data patterns and detecting anomalies, predictive maintenance becomes possible, allowing proactive repairs and replacement of parts before they fail. This approach minimizes unplanned downtime and extends the lifespan of equipment, ultimately reducing operational costs for both manufacturers and end-users.

3. Streamlined Inventory Management

Managing inventory can be a challenging task for manufacturers. IoT platforms enable real-time tracking and monitoring of consumables, spare parts, and raw materials. By automating inventory management, manufacturers can streamline their supply chains, ensuring timely replenishment and reducing stockouts or excess inventory. This leads to improved operational efficiency, lower inventory costs, and increased customer satisfaction due to timely deliveries.

4. Customized Solutions and Remote Assistance

Manufacturers can leverage IoT technology to provide personalized solutions and remote assistance to end-users. Through connectivity, real-time data sharing, and analysis, technicians can remotely diagnose issues, offer guidance, and even perform troubleshooting. This not only saves time and costs associated with on-site visits but also enables manufacturers to deliver faster and more efficient technical support to their customers.

5. Data-driven Decision Making and Business Intelligence

The data collected by IoT devices provides invaluable insights for both manufacturers and end-users. Manufacturers can analyze machine performance, operational efficiency, and usage patterns to identify areas for improvement, optimize production processes, and develop new product features. End-users can use the data to monitor their productivity, identify bottlenecks, and make informed decisions regarding equipment upgrades, maintenance schedules, and resource allocation.

Conclusion

The integration of IoT in the Arc Cutting Equipment industry has paved the way for a new era of efficiency, precision, and connectivity. Manufacturers can harness the power of real-time data collection, predictive maintenance, and remote assistance to enhance their operations, reduce costs, and provide superior customer service. With IoT as a driving force, the industry has the potential to further innovate and improve, meeting the evolving demands of industrial manufacturing in the digital age.

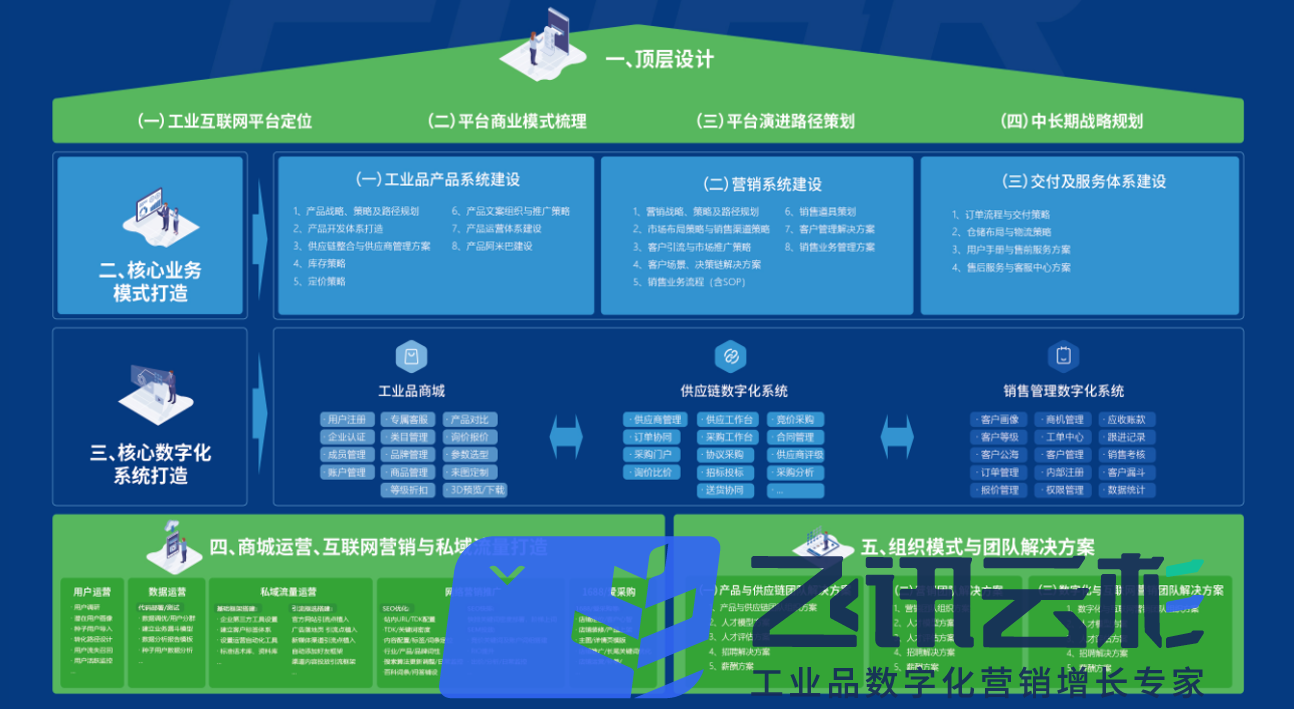

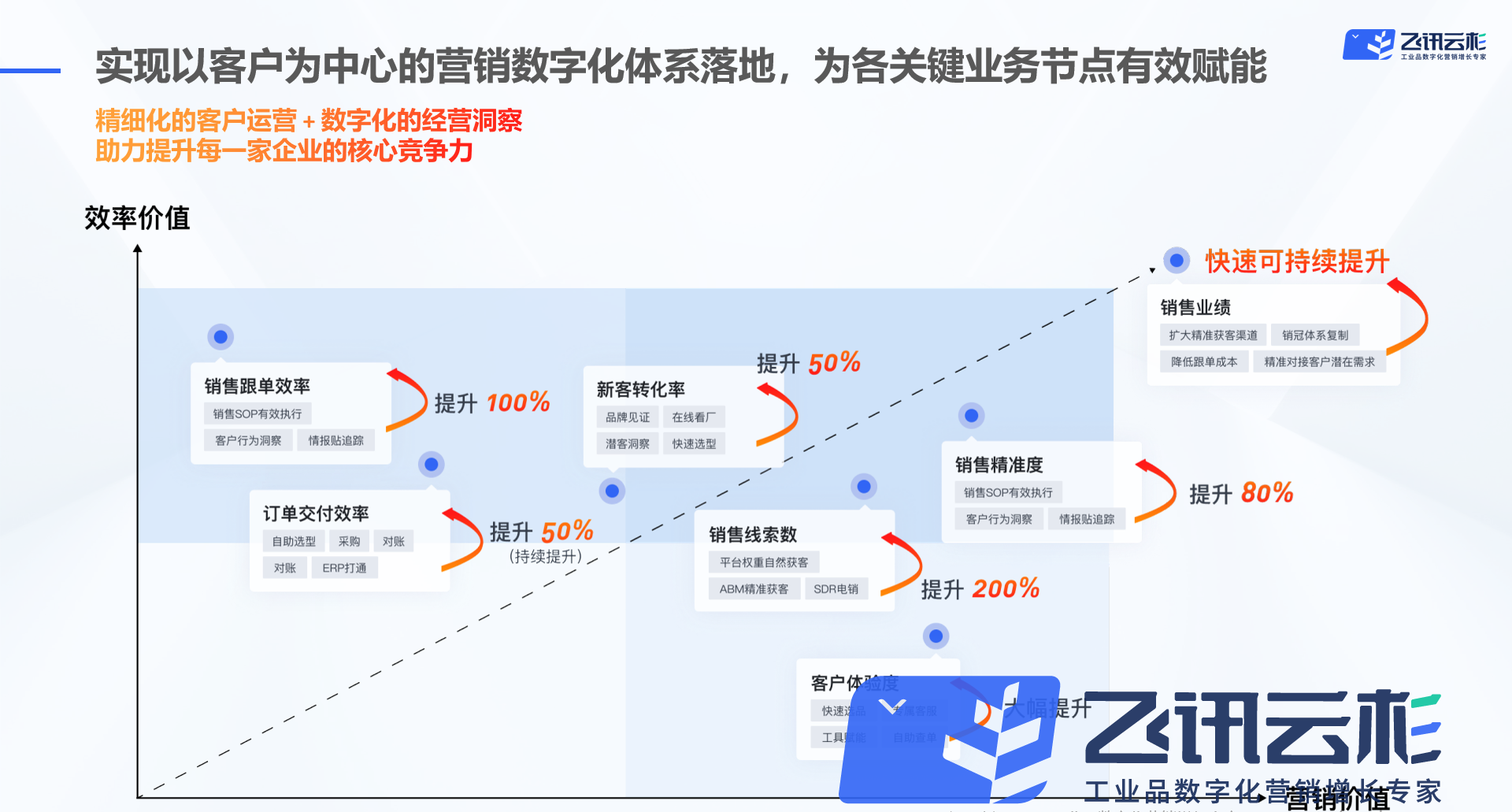

飞讯云杉是一家提供全链数字化营销解决方案的企业,聚焦产业互联网平台孵化服务,为工业制造企业搭建数字化营销-数字化供应链-业务智能决策全链数字化营销业务体系,实现工业品营销模式的创新,通过数字化赋能销售快速复制,让每一个工业品制造企业都拥有全链数字化营销业务体系。

请先 登录后发表评论 ~