除尘设备工业互联网平台孵化

Title: The Industrial Internet Platform Incubating Dust Removal Equipment

Introduction:

In recent years, with the rapid development of the industrial sector, the issue of environmental pollution has become a growing concern. Recognizing the importance of clean air in the workplace, the demand for efficient and reliable dust removal equipment has increased significantly. To meet this demand, the advent of the Industrial Internet has revolutionized the way dust removal equipment is manufactured, monitored, and maintained. In this article, we will explore how the Industrial Internet platform is transforming the dust removal industry and supporting the incubation of innovative technologies.

1. The Role of the Industrial Internet Platform:

The Industrial Internet platform serves as the backbone for connecting various components of the dust removal industry, including manufacturers, suppliers, service providers, and end users. It enables seamless communication, data sharing, and collaboration among different stakeholders, creating an ecosystem that fosters innovation and productivity.

2. Enhanced Efficiency through Real-time Monitoring:

One of the key benefits of the Industrial Internet platform is real-time monitoring. By equipping dust removal equipment with sensors and connectivity, manufacturers can collect valuable data on operational parameters such as air quality, pressure, temperature, and filter condition. This data is transmitted to the cloud, where advanced analytics algorithms process it, providing real-time insights and predictive maintenance suggestions. As a result, equipment downtime is reduced, and maintenance costs are optimized.

3. Intelligent Control and Optimization:

The integration of Artificial Intelligence (AI) algorithms into the Industrial Internet platform further enhances the efficiency of dust removal equipment. AI can analyze data patterns and optimize the system's performance by adjusting parameters, such as fan speed, filter cleaning frequency, and energy consumption. Through continuous learning and adaptation, the equipment can achieve optimal operation while minimizing energy waste.

4. Remote Operation and Troubleshooting:

With the Industrial Internet platform, operators and maintenance personnel can remotely monitor and control dust removal equipment, saving time and resources. Real-time access to equipment status allows operators to make timely adjustments and respond to potential issues promptly. Remote troubleshooting capabilities enable faster problem resolution, reducing downtime and improving overall productivity.

5. Predictive Maintenance and Reduced Costs:

Traditional maintenance practices often rely on fixed schedules or reactive responses. The Industrial Internet platform enables predictive maintenance, where algorithms analyze real-time data to identify potential faults before they occur. By proactively scheduling maintenance activities and replacing components based on actual usage, costs associated with unexpected breakdowns can be significantly reduced, while equipment lifespan is extended.

6. Collaboration and Innovation:

The Industrial Internet platform encourages collaboration among stakeholders in the dust removal industry. Manufacturers can work closely with suppliers and service providers to streamline the supply chain, improve product quality, and reduce lead times. Moreover, access to aggregated data from multiple sources facilitates innovation by providing insights into industry trends, customer preferences, and emerging technologies.

Conclusion:

The advent of the Industrial Internet platform has revolutionized the dust removal industry, transforming the way equipment is manufactured, monitored, and maintained. Through real-time monitoring, intelligent control, remote operation, and predictive maintenance, dust removal equipment has become more efficient, cost-effective, and environmentally friendly. The platform also fosters collaboration and innovation, supporting the incubation of new technologies and solutions. As the industrial sector continues to grow, the Industrial Internet platform will play a crucial role in ensuring cleaner and safer work environments.

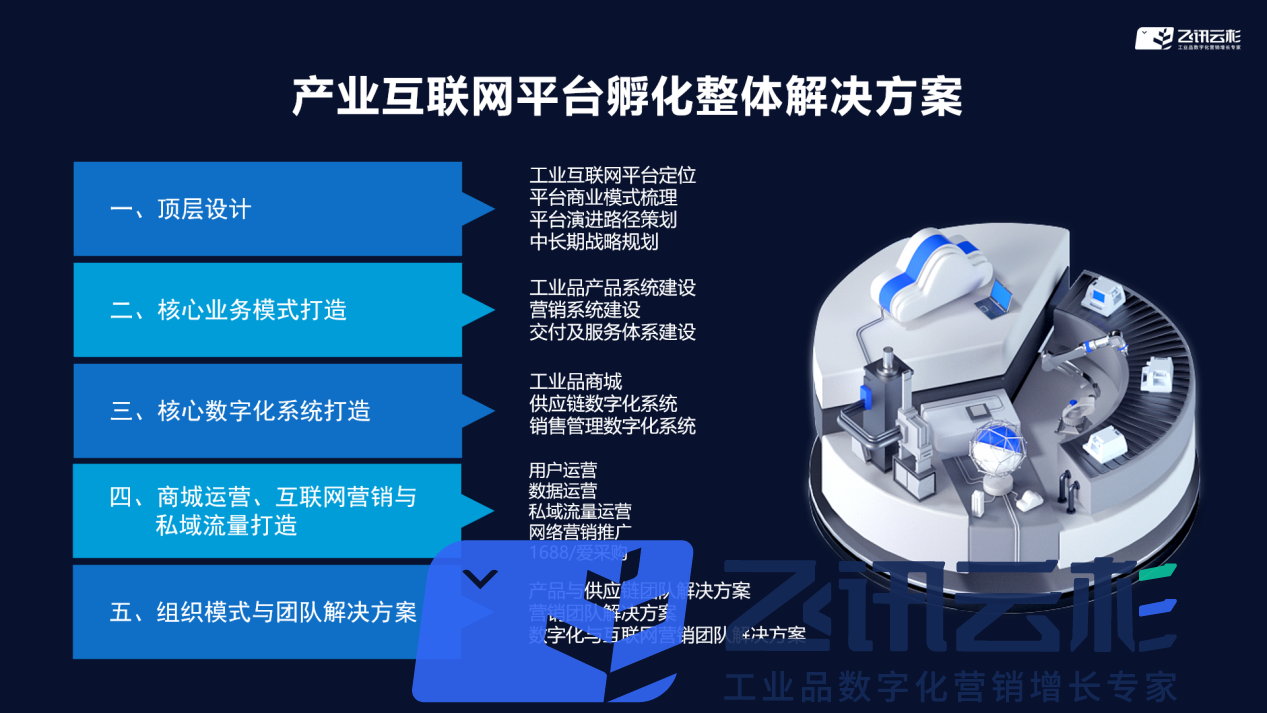

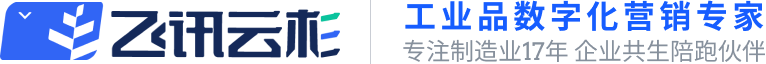

飞讯云杉是一家提供全链数字化营销解决方案的企业,聚焦产业互联网平台孵化服务,为工业制造企业搭建数字化营销-数字化供应链-业务智能决策全链数字化营销业务体系,实现工业品营销模式的创新,通过数字化赋能销售快速复制,让每一个工业品制造企业都拥有全链数字化营销业务体系。

请先 登录后发表评论 ~