工业过滤设备工业互联网平台打造

Title: Building an Industrial Internet Platform for Industrial Filtration Equipment

Introduction:

In recent years, the rapid development of the Industrial Internet has revolutionized various industries, enabling them to embrace digital transformation. One such industry is industrial filtration equipment, which plays a crucial role in maintaining clean and safe working environments. In this article, we will explore the significance of building an Industrial Internet platform specifically tailored for industrial filtration equipment.

1. Enhanced Monitoring and Control:

The integration of industrial filtration equipment with an Internet platform allows for real-time monitoring and control. By connecting sensors and data acquisition systems, operators can remotely monitor the performance and operational status of filtration devices. This ensures timely detection of any potential issues, reducing downtime and improving overall efficiency.

2. Predictive Maintenance:

With an Industrial Internet platform, predictive maintenance becomes possible. By analyzing real-time data collected from filtration equipment, algorithms can identify patterns and anomalies, enabling operators to schedule maintenance tasks proactively. This approach minimizes unexpected breakdowns, optimizes equipment utilization, and reduces maintenance costs.

3. Data Analytics and Decision Support:

An Industrial Internet platform facilitates the collection and analysis of vast amounts of operational data from industrial filtration equipment. Advanced data analytics techniques, such as machine learning and artificial intelligence, can extract valuable insights and trends. These insights can then be used to optimize filtration processes, improve product quality, and enhance overall productivity.

4. Resource Optimization:

Industrial filtration equipment often requires the consumption of resources such as water, energy, and consumables. An Industrial Internet platform enables the monitoring and optimization of resource consumption in real-time. By collecting data on resource usage patterns, fine-tuning operational parameters, and implementing intelligent control algorithms, significant reductions in resource waste can be achieved, leading to cost savings and environmental benefits.

5. Remote Collaboration and Knowledge Sharing:

An Industrial Internet platform can serve as a collaborative hub, connecting various stakeholders within the industrial filtration ecosystem. Equipment manufacturers, maintenance technicians, and operators can communicate and share knowledge seamlessly. This fosters a collaborative environment where best practices can be exchanged, problems can be solved collectively, and innovation can flourish.

6. Customization and Scalability:

Every industrial filtration system has unique requirements based on the specific industry, application, and regulations. An Industrial Internet platform provides the flexibility to customize and scale the functionalities according to individual needs. Whether it is adding new sensors, integrating with existing systems, or expanding the platform's capabilities, adaptability to diverse environments is a significant advantage.

Conclusion:

The Industrial Internet platform for industrial filtration equipment empowers manufacturers, operators, and technicians with valuable insights, real-time control, and predictive maintenance capabilities. It enhances productivity, reduces downtime, optimizes resource utilization, and promotes collaboration within the industry. As we embrace the digital era, building an Industrial Internet platform tailored for industrial filtration equipment is no longer a luxury but a necessity to stay competitive and ensure sustainable growth.

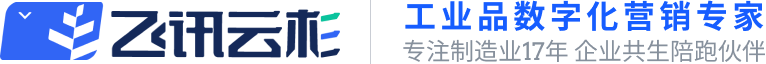

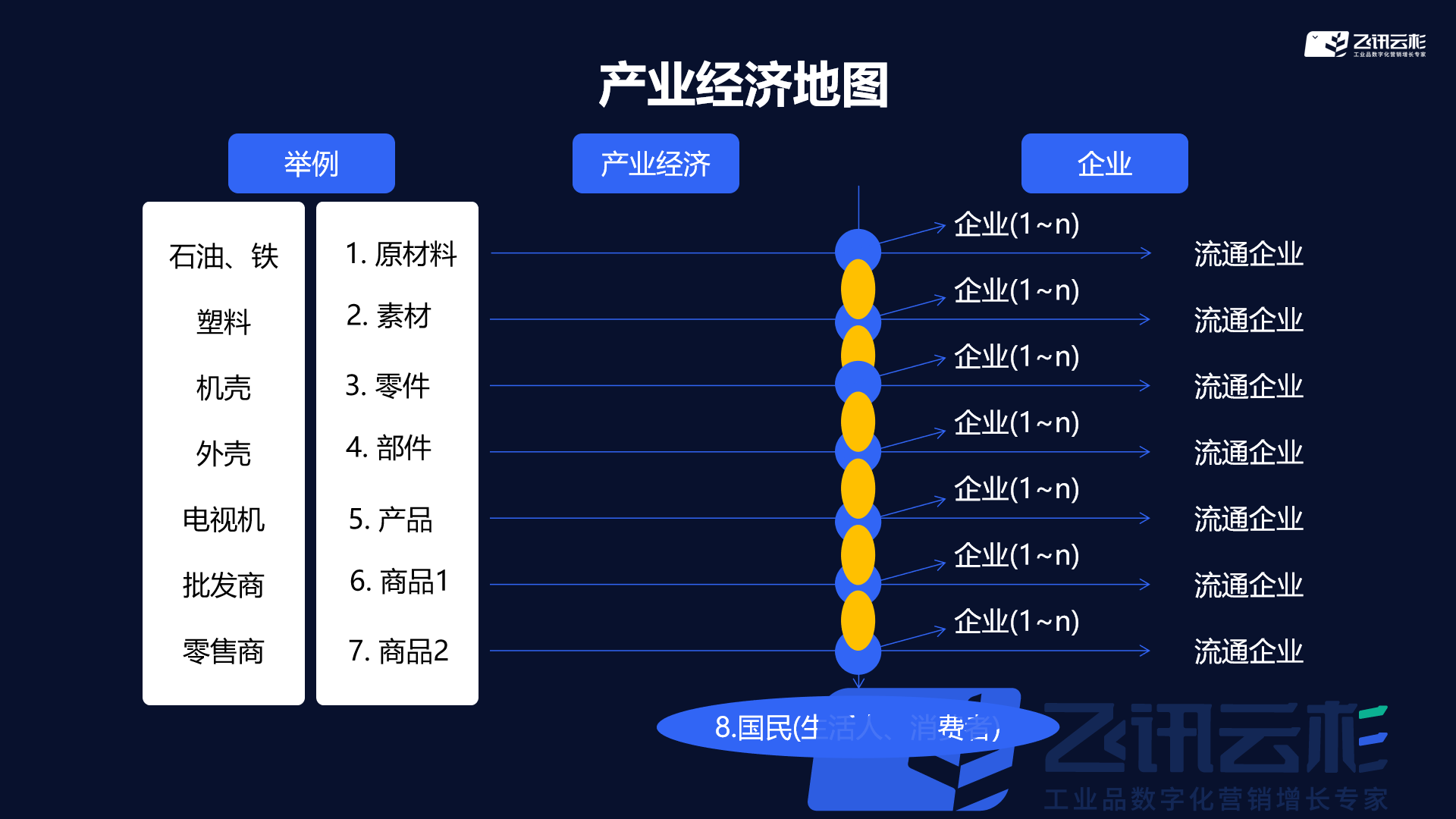

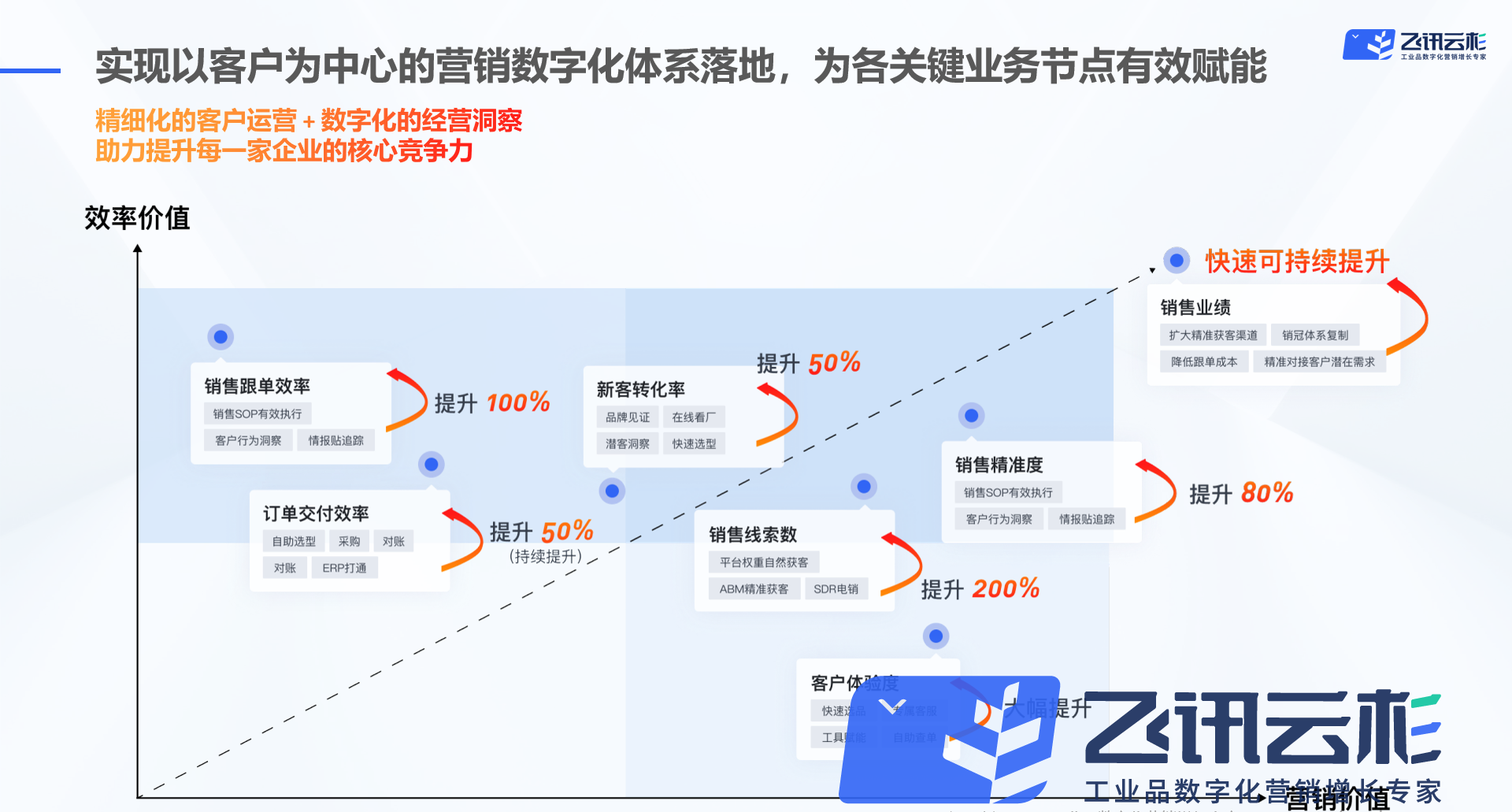

飞讯云杉是一家提供全链数字化营销解决方案的企业,聚焦产业互联网平台孵化服务,为工业制造企业搭建数字化营销-数字化供应链-业务智能决策全链数字化营销业务体系,实现工业品营销模式的创新,通过数字化赋能销售快速复制,让每一个工业品制造企业都拥有全链数字化营销业务体系。

请先 登录后发表评论 ~