电弧切割设备工业互联网平台服务商

Title: The Industrial Internet of Things Transforms the Arc Cutting Equipment Industry

Introduction:

In recent years, with the rapid development of the industrial internet of things (IIoT), traditional industries have been undergoing a digital transformation. This transformation has opened up new opportunities for arc cutting equipment, leading to significant advancements in efficiency, productivity, and safety. As a leading service provider in the field of arc cutting equipment for the industrial internet platform, we have witnessed firsthand the transformative power of IIoT. In this article, we will explore how the IIoT is revolutionizing the arc cutting equipment industry.

1. Enhanced Connectivity and Real-time Monitoring:

The integration of IIoT technology into arc cutting equipment enables seamless connectivity between machines, operators, and production systems. Through a centralized industrial internet platform, real-time monitoring of machine data, such as temperature, voltage, and consumption, is made possible. This allows operators and technicians to closely monitor the operating conditions of the equipment, ensuring optimal performance and minimizing downtime. With the ability to detect abnormalities and predict maintenance requirements, manufacturers can proactively address issues, leading to improved efficiency and reduced costs.

2. Intelligent Data Analysis and Predictive Maintenance:

With the advent of IIoT, vast amounts of data are generated by arc cutting equipment during operation. However, the true value lies in the analysis and utilization of this data. By employing advanced analytics tools and algorithms, the industrial internet platform can process and analyze this data, providing valuable insights into machine performance, energy consumption, and maintenance requirements. This enables manufacturers to implement predictive maintenance strategies, reducing the risk of unexpected breakdowns and optimizing equipment lifespan.

3. Automation and Optimization:

Arc cutting equipment integrated with IIoT capabilities can be programmed to perform tasks automatically, reducing manual intervention and improving operational efficiency. By utilizing sensors and actuators, machines can collect real-time data on cutting parameters, material properties, and environmental conditions. This data can be leveraged to optimize cutting processes, ensuring precision and consistency. Additionally, the integration of IIoT with other technologies such as artificial intelligence and machine learning enables machines to learn from previous operations, adapt to changing conditions, and continuously improve performance.

4. Remote Monitoring and Assistance:

The IIoT has brought remote monitoring and assistance capabilities to the arc cutting equipment industry. With the industrial internet platform, operators and technicians can remotely monitor equipment performance, troubleshoot issues, and provide guidance to on-site personnel. This eliminates the need for constant physical presence and enables rapid response to emergencies or technical difficulties. Remote assistance also allows manufacturers to provide timely support and improve customer satisfaction.

5. Safety and Risk Mitigation:

Safety is a top priority in the manufacturing industry. The IIoT plays a crucial role in improving safety measures for arc cutting equipment. Integrated sensors and real-time data monitoring enable early detection of potential safety hazards, such as overheating, gas leaks, or abnormal vibrations. Alerts and notifications can be sent to operators or supervisors, ensuring prompt action is taken to mitigate risks. Furthermore, historical data analysis can identify patterns and trends related to safety incidents, facilitating the development of preventive measures and enhancing overall workplace safety.

Conclusion:

The industrial internet of things has revolutionized the arc cutting equipment industry, leading to increased efficiency, productivity, and safety. Through enhanced connectivity, intelligent data analysis, automation, and remote monitoring, manufacturers can optimize operational performance and provide better customer support. As a service provider in the field of arc cutting equipment for the industrial internet platform, we are committed to harnessing the power of IIoT to drive innovation and transform industries. Embracing the IIoT is not only the future of arc cutting equipment but also a catalyst for progress in the manufacturing sector as a whole.

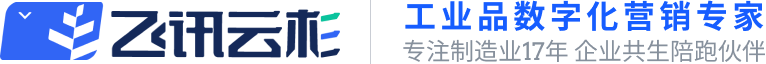

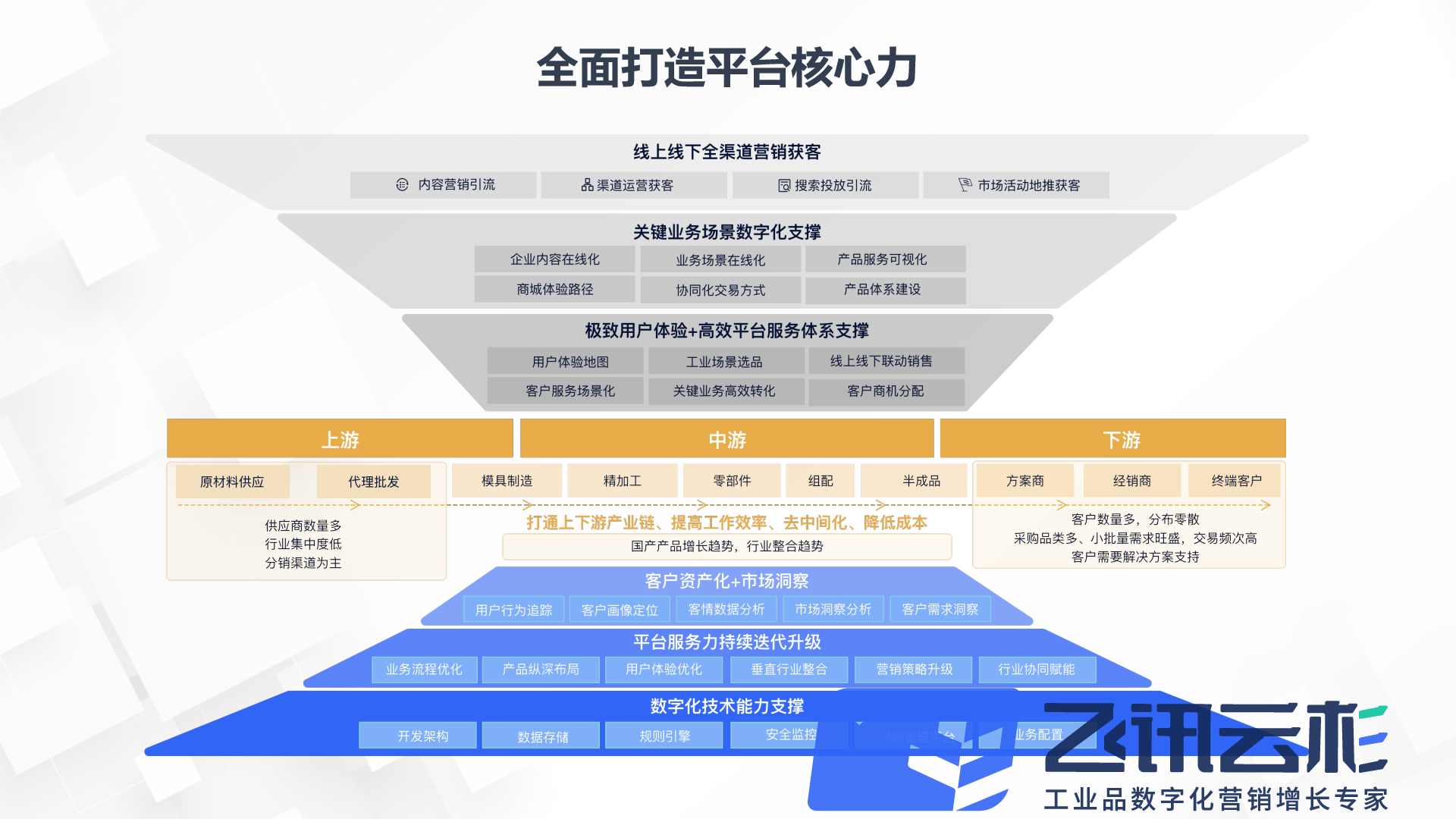

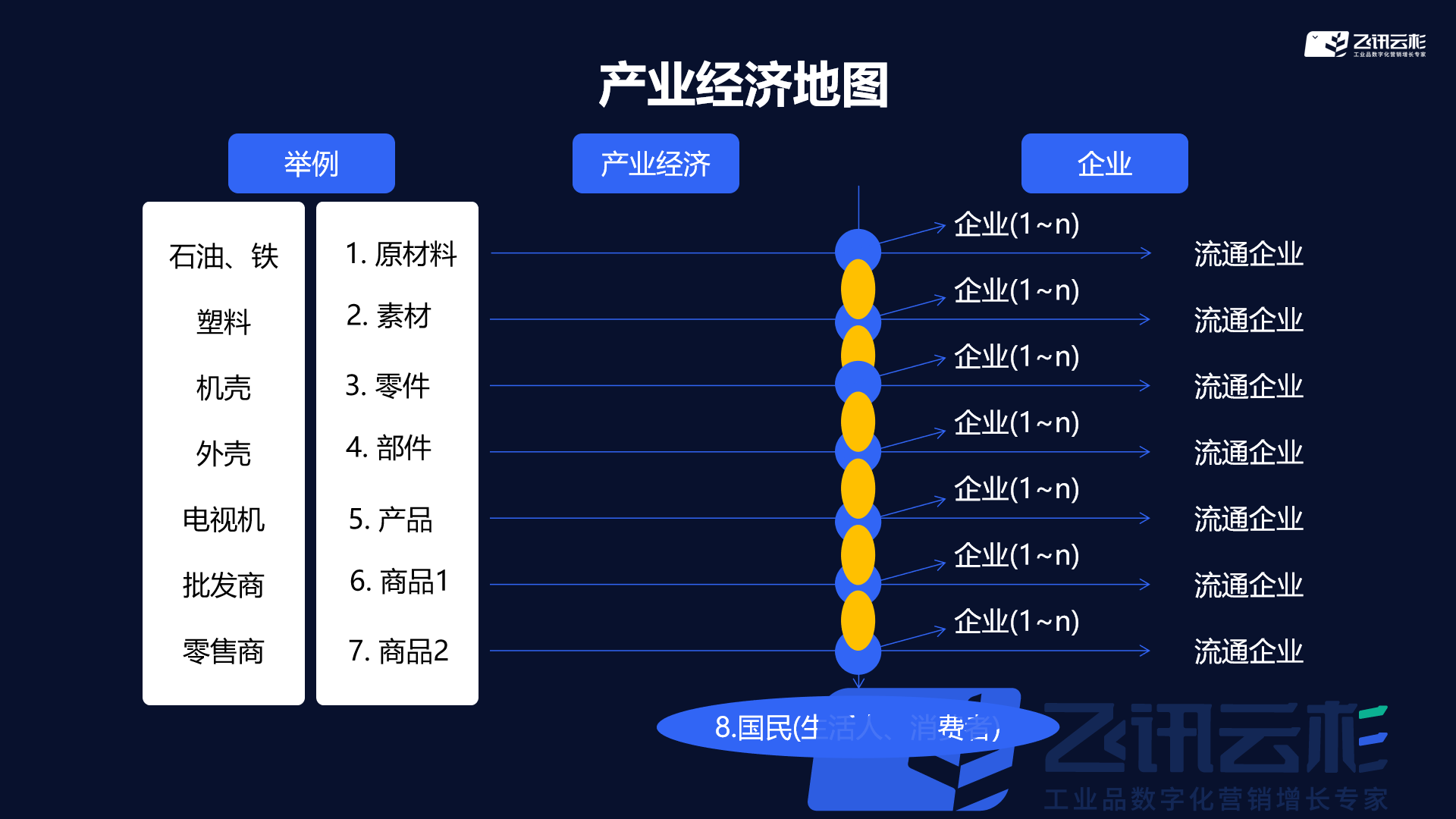

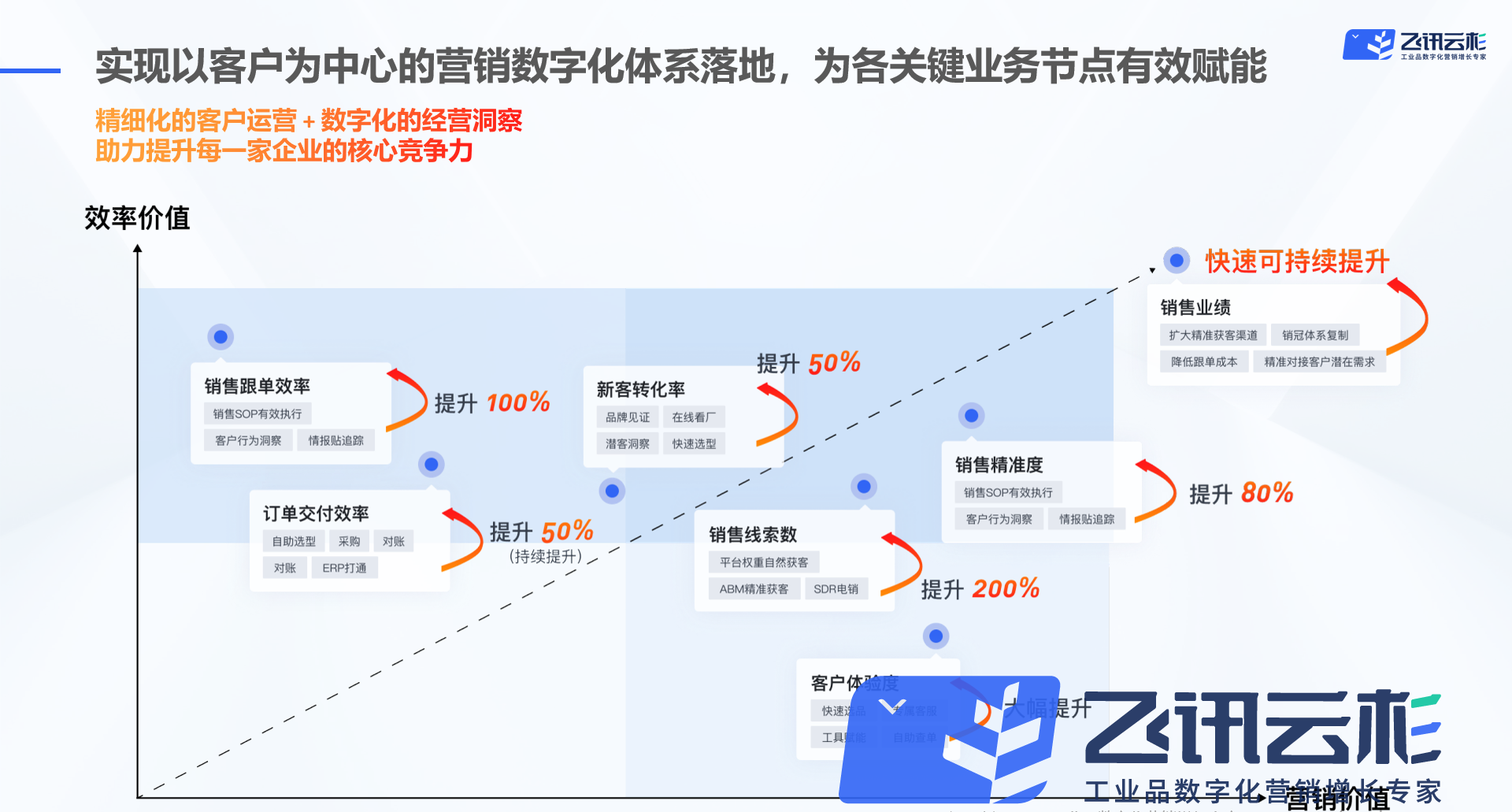

飞讯云杉是一家提供全链数字化营销解决方案的企业,聚焦产业互联网平台孵化服务,为工业制造企业搭建数字化营销-数字化供应链-业务智能决策全链数字化营销业务体系,实现工业品营销模式的创新,通过数字化赋能销售快速复制,让每一个工业品制造企业都拥有全链数字化营销业务体系。

请先 登录后发表评论 ~