工业流量计产业互联网平台开发公司

Title: The Emergence of Industrial Flowmeter Industrial Internet Platforms

Introduction:

With the rapid development of the Internet and emerging technologies, various industries are undergoing a transformational shift towards digitization. In today's industrial landscape, the Industrial Internet of Things (IIoT) has become a critical component for optimizing operational processes and enhancing efficiency. In this article, we will explore the role of Industrial Internet platforms in the development and advancement of the industrial flowmeter sector.

1. The Need for Industrial Flowmeter Industry Internet Platforms:

Industrial flowmeters play a crucial role in measuring and monitoring fluid flows within industrial processes. They provide accurate data on the volume, velocity, and quality of fluids passing through pipelines, enabling businesses to optimize their operations, ensure product quality, and minimize wastage. However, the traditional flowmeter industry often faced challenges such as limited connectivity, lack of real-time data analysis, and manual intervention for maintenance and calibration.

To address these challenges, the emergence of industrial flowmeter industry internet platforms became imperative. These platforms integrate flowmeters with advanced IoT technologies, cloud computing, and data analytics, facilitating seamless connectivity and real-time monitoring. By harnessing the power of the Industrial Internet, these platforms revolutionize the way flowmeters are used and managed in industrial settings.

2. Key Features and Benefits of Industrial Flowmeter Industry Internet Platforms:

a. Real-time Monitoring and Data Analytics:

Industrial flowmeter industry internet platforms collect data from flowmeters in real-time and provide comprehensive insights into flow patterns, pressure differentials, and temperature variations. With advanced analytics capabilities, crucial parameters can be analyzed, allowing for proactive interventions and preventive maintenance. This enhances operational efficiency and reduces downtime caused by unexpected breakdowns.

b. Remote Access and Control:

Through secure cloud-based platforms, authorized personnel can remotely access and control flowmeters from anywhere, anytime. This feature streamlines maintenance procedures, reduces the need for on-site visits, and increases operational convenience. Technicians can monitor multiple flowmeters simultaneously, identify potential issues, and take immediate action, minimizing response time.

c. Scalability and Integration:

Industrial flowmeter industry internet platforms are designed to be scalable and adaptable to evolving business needs. They can be seamlessly integrated with existing industrial systems and infrastructure, ensuring compatibility and interoperability. This allows for a holistic approach to data management and streamlines the overall operational process.

d. Enhanced Efficiency and Cost Reduction:

By leveraging real-time data and predictive analytics, flowmeters can be optimized for maximum efficiency, reducing energy consumption and overall costs. Improved accuracy in measurements minimizes material wastage, enhances product quality, and optimizes resource allocation. Additionally, remote monitoring capabilities eliminate the need for frequent manual checks and reduce labor costs.

3. Future Prospects and Challenges:

The development of industrial flowmeter industry internet platforms presents significant opportunities for growth and innovation. As more businesses adopt these platforms, the demand for advanced flowmeter models with IoT capabilities will increase. The integration of artificial intelligence (AI) and machine learning algorithms will further enhance predictive maintenance and fault detection capabilities.

However, challenges remain. Ensuring data security and privacy is paramount in an interconnected environment. Robust cybersecurity measures must be implemented to protect against potential threats and breaches. Additionally, the standardization of communication protocols and interoperability between different flowmeter brands and platforms needs to be addressed for widespread adoption.

Conclusion:

Industrial flowmeter industry internet platforms provide a transformative solution for optimizing flowmeter performance, data management, and operational efficiency. By harnessing the power of the Industrial Internet, businesses can unlock new opportunities for growth, reduce costs, and enhance overall competitiveness. The continuous evolution and integration of advanced technologies will undoubtedly drive the flowmeter industry towards a digital future.

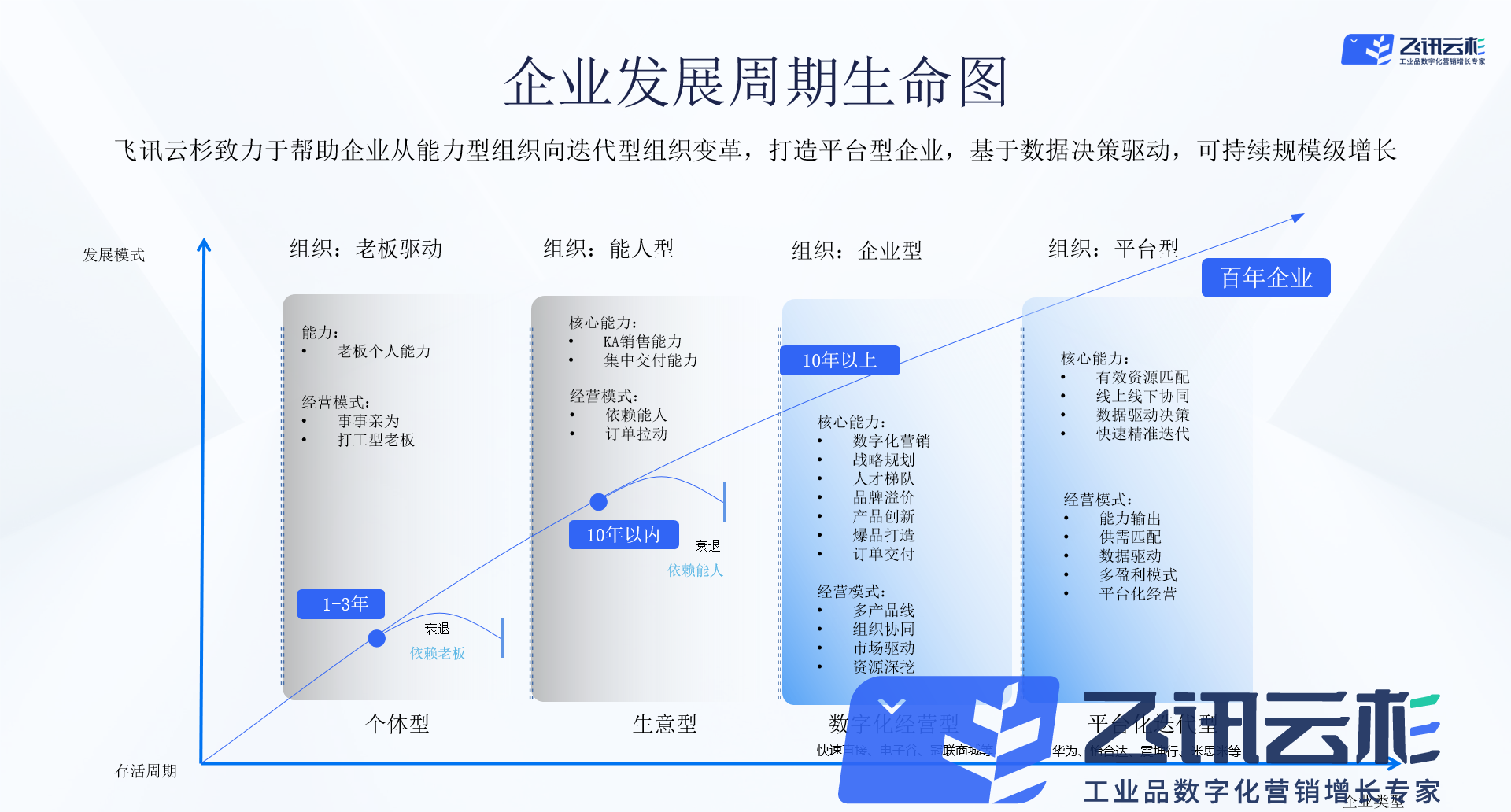

飞讯云杉是一家提供全链数字化营销解决方案的企业,聚焦产业互联网平台孵化服务,为工业制造企业搭建数字化营销-数字化供应链-业务智能决策全链数字化营销业务体系,实现工业品营销模式的创新,通过数字化赋能销售快速复制,让每一个工业品制造企业都拥有全链数字化营销业务体系。

请先 登录后发表评论 ~