工业涂覆设备产业互联网平台孵化

Title: The Birth of Industrial Coating Equipment Industry Internet Platform

Introduction

The rapid development of the Internet has brought about revolutionary changes in various industries, including the industrial coating equipment industry. The emergence of the Industrial Coating Equipment Industry Internet Platform has further promoted the integration of digital technology and traditional industries, leading to a new era of intelligent manufacturing. In this article, we will explore the significance of the platform's incubation and its potential impact on the industry.

1. Background

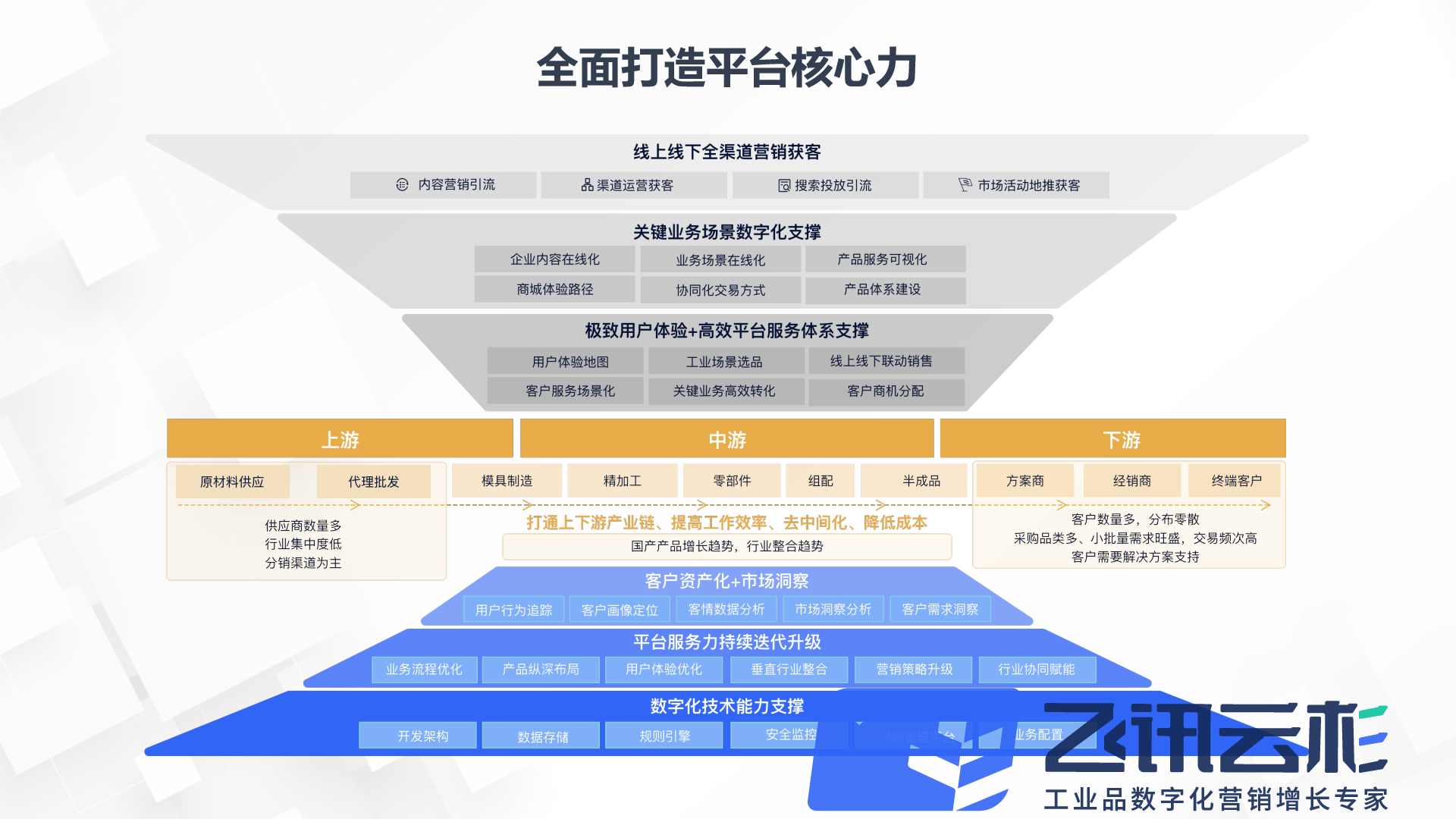

Industrial coating equipment plays a crucial role in various manufacturing sectors, such as automotive, aerospace, and electronics. However, traditional coating equipment often faces challenges such as inefficient coordination, lack of real-time data analysis, and difficulty in equipment maintenance and management. To address these issues, the concept of an industry internet platform specifically designed for industrial coating equipment emerged.

2. Incubation of the Industrial Coating Equipment Industry Internet Platform

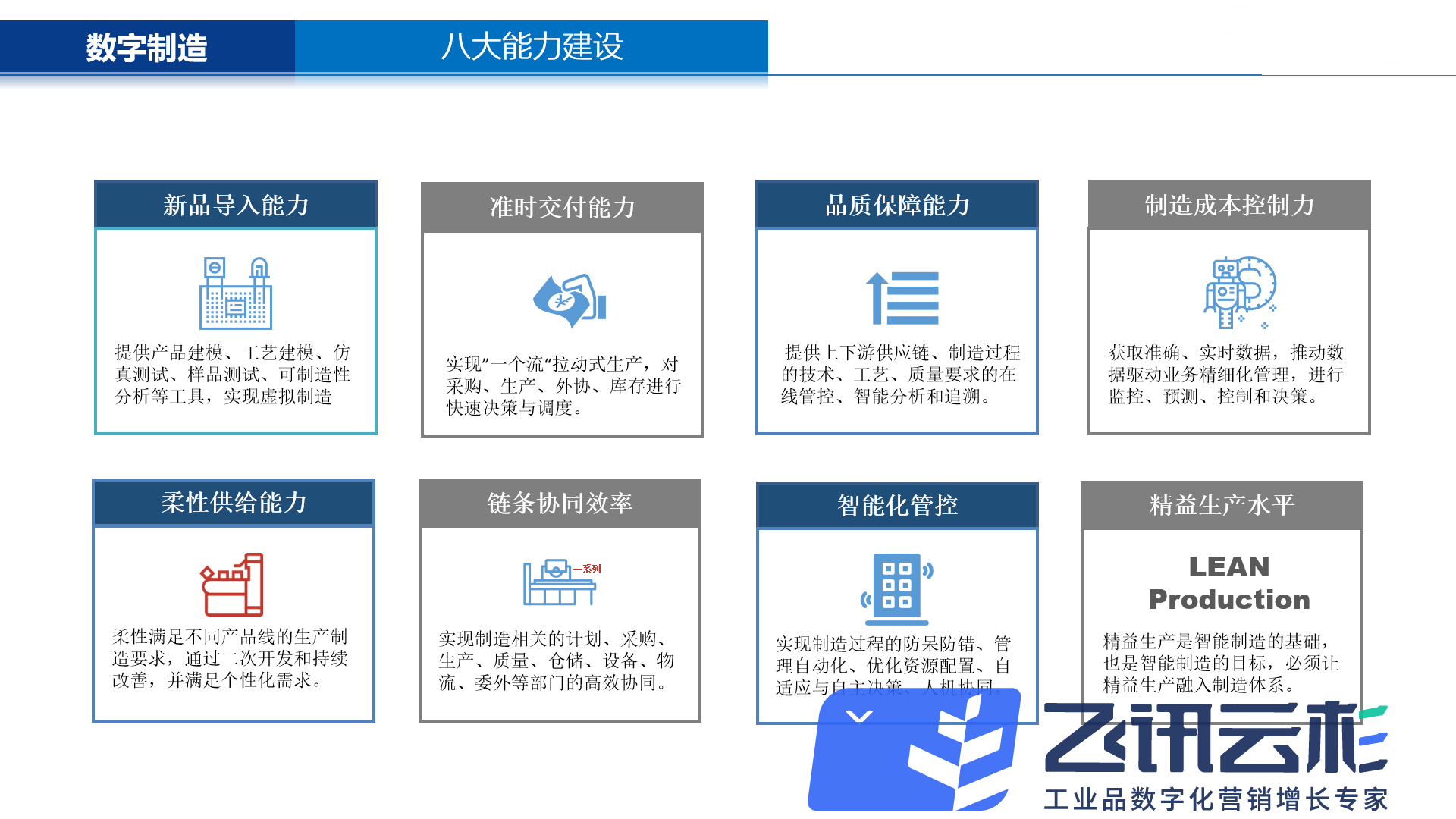

The incubation of the Industrial Coating Equipment Industry Internet Platform involves multiple stages. Firstly, a group of experts and industry professionals collaborate to define the platform's vision and goals. They identify the pain points and challenges faced by the industry, such as equipment utilization, quality control, and resource allocation. Based on these insights, a comprehensive plan is formulated to integrate digital technologies, including the Internet of Things (IoT), big data analytics, and artificial intelligence (AI).

3. Key Features and Functions

The Industrial Coating Equipment Industry Internet Platform offers a wide range of features and functions that improve efficiency and streamline operations. These include:

- Real-time monitoring: Sensors installed in coating equipment collect and transmit real-time data to the platform, allowing operators to monitor equipment status, performance, and energy consumption remotely.

- Predictive maintenance: By analyzing historical data and implementing AI algorithms, the platform can predict equipment failures and recommend maintenance schedules, minimizing downtime and reducing maintenance costs.

- Intelligent scheduling: Through advanced algorithms and machine learning capabilities, the platform optimizes equipment utilization, production planning, and resource allocation, facilitating smooth production processes.

- Quality control: Data analysis and AI technology enable real-time quality monitoring, ensuring compliance with industry standards and reducing defects.

4. Benefits and Impacts

The Industrial Coating Equipment Industry Internet Platform brings significant benefits and impacts to both manufacturers and the industry as a whole:

- Improved efficiency: Real-time monitoring and predictive maintenance reduce unplanned downtime, enhancing overall equipment effectiveness (OEE) and production efficiency.

- Enhanced quality control: The platform enables real-time data collection and analysis, enabling manufacturers to identify and rectify quality issues promptly.

- Cost reduction: By optimizing production planning, resource allocation, and maintenance schedules, manufacturers can minimize operational costs and increase profit margins.

- Intelligent decision-making: The platform provides manufacturers with comprehensive and accurate data insights, enabling them to make informed decisions, improve business strategies, and seize opportunities.

- Industry collaboration: The platform serves as a hub for industry stakeholders to exchange information, share best practices, and collaborate on research and development, fostering innovation and driving industry growth.

Conclusion

The incubation of the Industrial Coating Equipment Industry Internet Platform marks a significant milestone in the industry's digital transformation journey. By leveraging the power of IoT, big data analytics, and AI, the platform revolutionizes traditional coating equipment operations, leading to improved efficiency, enhanced quality control, and reduced costs. As more manufacturers embrace this technology, the industry as a whole will witness unprecedented growth and advancement towards intelligent manufacturing.

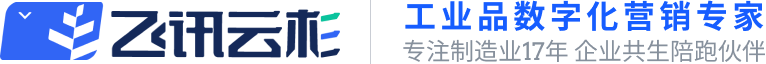

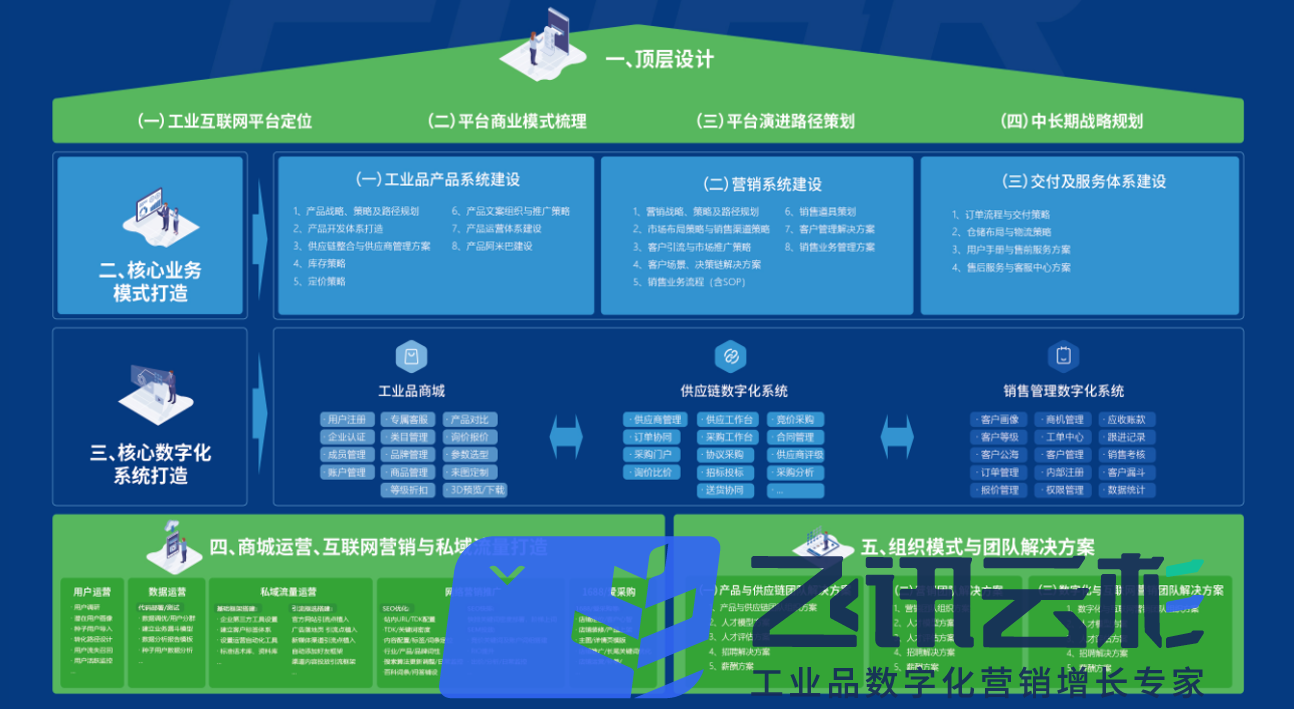

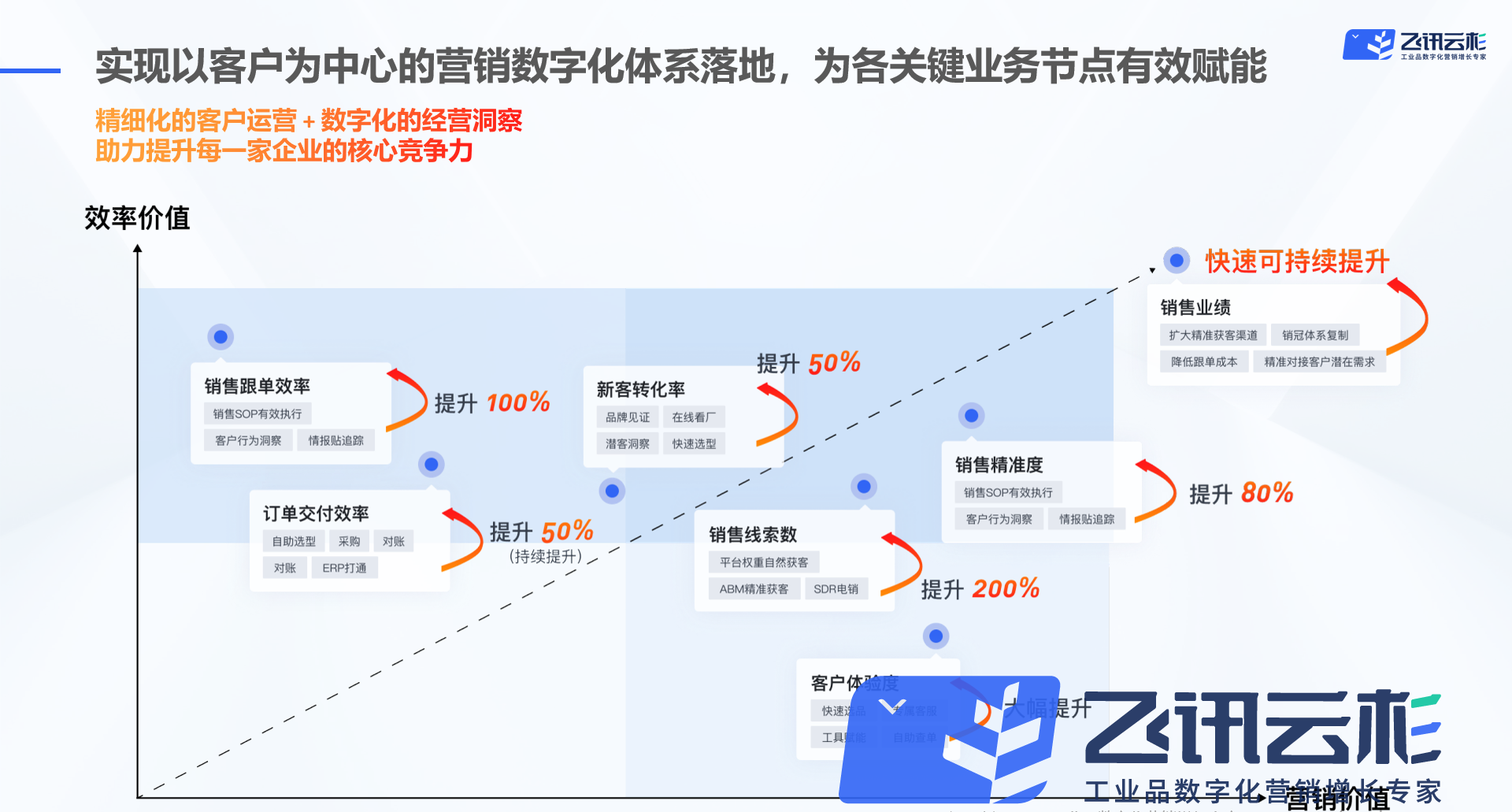

飞讯云杉是一家提供全链数字化营销解决方案的企业,聚焦产业互联网平台孵化服务,为工业制造企业搭建数字化营销-数字化供应链-业务智能决策全链数字化营销业务体系,实现工业品营销模式的创新,通过数字化赋能销售快速复制,让每一个工业品制造企业都拥有全链数字化营销业务体系。

请先 登录后发表评论 ~