工业燃烧设备工业互联网平台系统搭建

Title: Building an Industrial Internet Platform System for Industrial Combustion Equipment

Introduction:

With the rapid development of the Industrial Internet of Things (IIoT), various industries are seeking to optimize their operational efficiency and maximize productivity. One such industry is the field of industrial combustion equipment. By implementing an industrial Internet platform system, companies can enhance their equipment management, monitoring, and control capabilities, leading to improved safety, energy efficiency, and cost-effectiveness. In this article, we will delve into the process of building a comprehensive industrial Internet platform system for industrial combustion equipment.

I. Understanding Industrial Combustion Equipment:

Industrial combustion equipment plays a vital role in numerous sectors, including power generation, manufacturing, and chemical processing. These devices consume fossil fuels, biomass, or waste materials to produce heat, steam, or electricity. It is essential to have real-time data on the fuel consumption, temperature, emissions, and performance of these systems to ensure optimal operations and environmental compliance.

II. Components of an Industrial Internet Platform System:

1. Data Acquisition: The first step in building an industrial Internet platform system is to collect data from the combustion equipment. This can be achieved through various sensors and devices, such as temperature sensors, flow meters, pressure transmitters, and emission analyzers. The data collected needs to be transmitted securely to a central server for further analysis and processing.

2. Data Storage and Management: The collected data must be stored in a reliable and scalable database. Cloud-based solutions are often preferred, as they offer flexibility, accessibility, and easy integration with other systems. A robust data management system should be implemented to organize and retrieve data efficiently.

3. Real-time Monitoring and Control: To ensure the optimal and safe operation of industrial combustion equipment, real-time monitoring and control capabilities are crucial. An industrial Internet platform system should provide a user-friendly interface that allows operators to visualize the system's status, track key performance indicators, and receive alarms or alerts in case of abnormal conditions.

4. Data Analysis and Predictive Maintenance: Utilizing data analytics techniques, such as machine learning algorithms, the industrial Internet platform system can identify patterns and anomalies in the collected data. This enables predictive maintenance, where potential equipment failures can be predicted, and proactive measures can be taken to prevent unplanned downtime.

5. Integration with External Systems: An industrial Internet platform system should have the ability to integrate with other enterprise systems, such as enterprise resource planning (ERP) systems and customer relationship management (CRM) systems. This integration allows for streamlined operations, improved supply chain management, and better customer service.

III. Benefits of an Industrial Internet Platform System:

The implementation of an industrial Internet platform system for industrial combustion equipment offers several benefits:

1. Enhanced Safety: Real-time monitoring and control enable operators to detect and respond promptly to potential safety hazards, ensuring a safe working environment.

2. Improved Efficiency: By analyzing operational data, the system can identify inefficiencies and suggest optimization strategies, leading to reduced energy consumption and increased productivity.

3. Cost Reduction: Predictive maintenance helps prevent unplanned downtime, reducing maintenance costs and optimizing spare parts inventory.

4. Compliance with Regulations: With precise monitoring and accurate emissions data, companies can easily comply with environmental regulations and reduce their carbon footprint.

Conclusion:

Building an industrial Internet platform system for industrial combustion equipment is a strategic move towards achieving operational excellence, maximizing efficiency, and maintaining a competitive edge in the market. The system's components, including data acquisition, storage, real-time monitoring, data analysis, and integration with external systems, create a comprehensive solution that brings numerous benefits to the company. Embracing the Industrial Internet of Things revolutionizes the way industrial combustion equipment is managed, paving the way for a more sustainable and technologically advanced future.

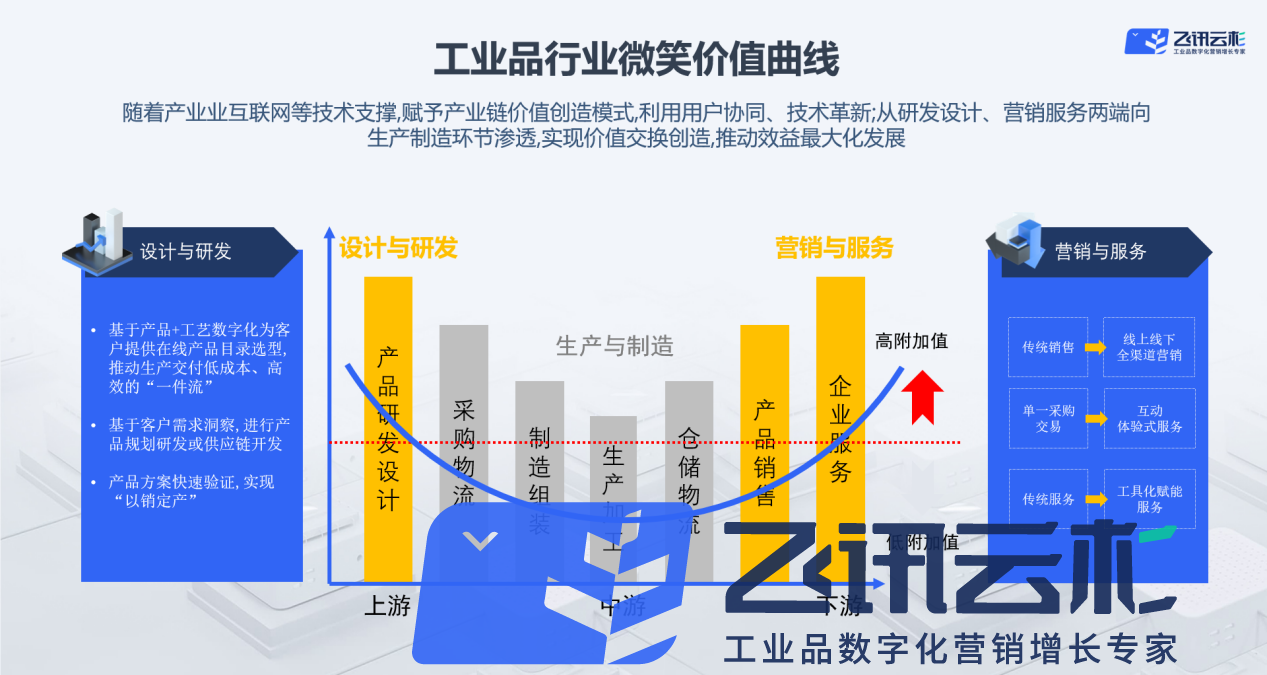

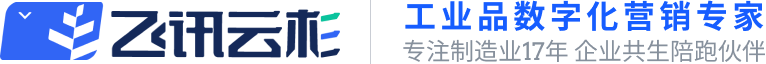

飞讯云杉是一家提供全链数字化营销解决方案的企业,聚焦产业互联网平台孵化服务,为工业制造企业搭建数字化营销-数字化供应链-业务智能决策全链数字化营销业务体系,实现工业品营销模式的创新,通过数字化赋能销售快速复制,让每一个工业品制造企业都拥有全链数字化营销业务体系。

请先 登录后发表评论 ~