工业输送带产业运营平台开发公司

Title: Empowering Industrial Conveyor Belt Operations through Platform Development

Introduction:

In recent years, the industrial sector has witnessed a significant transformation with the integration of advanced technologies. One such area is the development of industrial conveyor belt operation platforms, which have revolutionized the efficiency and productivity of manufacturing processes. These platforms serve as the backbone of several industries, enabling seamless coordination and optimization of material transportation. This article aims to explore the importance of industrial conveyor belt operation platforms and the benefits they bring to the manufacturing sector.

1. Streamlining Operations:

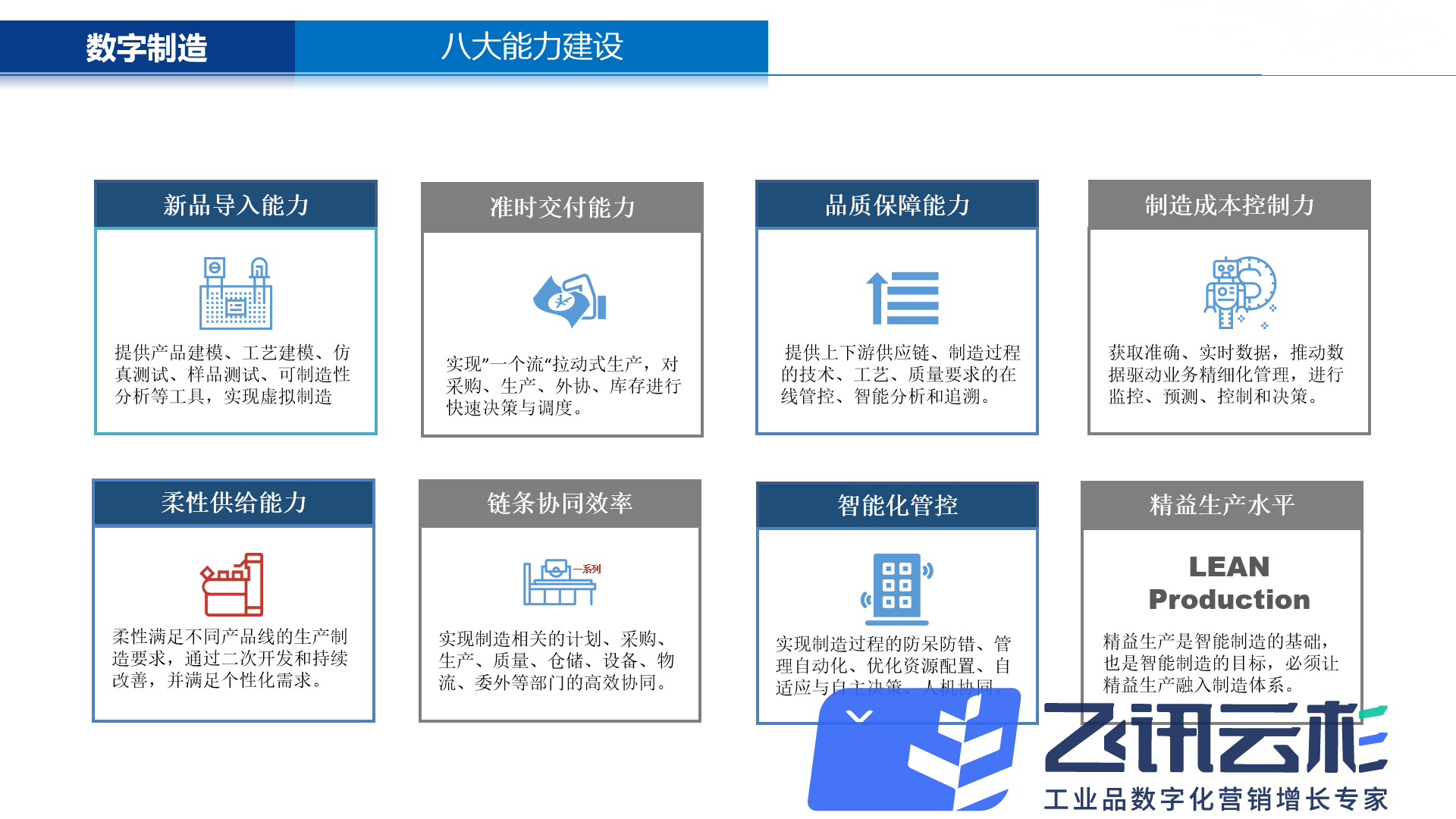

Industrial conveyor belt operation platforms serve as a centralized hub for monitoring and controlling the entire production system. Through real-time data collection and analysis, these platforms provide valuable insights into various aspects of manufacturing, such as equipment performance, production output, and material flow. By streamlining operations, manufacturers can identify bottlenecks, optimize workflows, and make informed decisions to enhance efficiency and productivity.

2. Improved Efficiency and Productivity:

Efficiency is crucial in today's competitive manufacturing landscape. Conveyor belt operation platforms leverage automation and intelligent algorithms to streamline processes and eliminate manual interventions. This automation reduces human errors and ensures consistent and accurate performance. Moreover, by optimizing material flow, minimizing downtime, and reducing idle time between processes, manufacturers can significantly improve productivity and enhance overall operational performance.

3. Enhanced Safety Measures:

Safety is of paramount importance in any industrial setting. Conveyor belt operation platforms are equipped with advanced sensing technologies and monitoring systems that detect potential hazards, such as oversized objects or abnormal vibrations. In case of emergencies or malfunctions, these platforms can quickly alert operators and initiate safety protocols, minimizing risks and ensuring a safe working environment for employees.

4. Predictive Maintenance:

Unplanned equipment breakdowns can lead to costly production delays and decreased efficiency. Conveyor belt operation platforms integrate predictive maintenance techniques that monitor the health and performance of machinery in real-time. Through continuous data analysis and machine learning algorithms, these platforms can predict potential failures and initiate maintenance activities before breakdowns occur. This proactive approach minimizes downtime, extends equipment lifespan, and optimizes maintenance costs.

5. Data-driven Decision Making:

Data is the backbone of modern manufacturing, and conveyor belt operation platforms generate a wealth of valuable insights. By collecting and analyzing data from various sources, such as sensors, machines, and production lines, manufacturers can make data-driven decisions to optimize processes, improve resource allocation, and identify areas for continuous improvement. This data-driven decision-making approach enables manufacturers to stay agile and adapt to changing market demands.

Conclusion:

The development of industrial conveyor belt operation platforms has transformed the manufacturing sector. By streamlining operations, enhancing efficiency and productivity, ensuring safety measures, enabling predictive maintenance, and facilitating data-driven decision making, these platforms empower manufacturers to stay competitive in an increasingly dynamic market. As technology continues to evolve, the potential for further advancements in conveyor belt operation platforms holds promising prospects for the future of industrial automation.

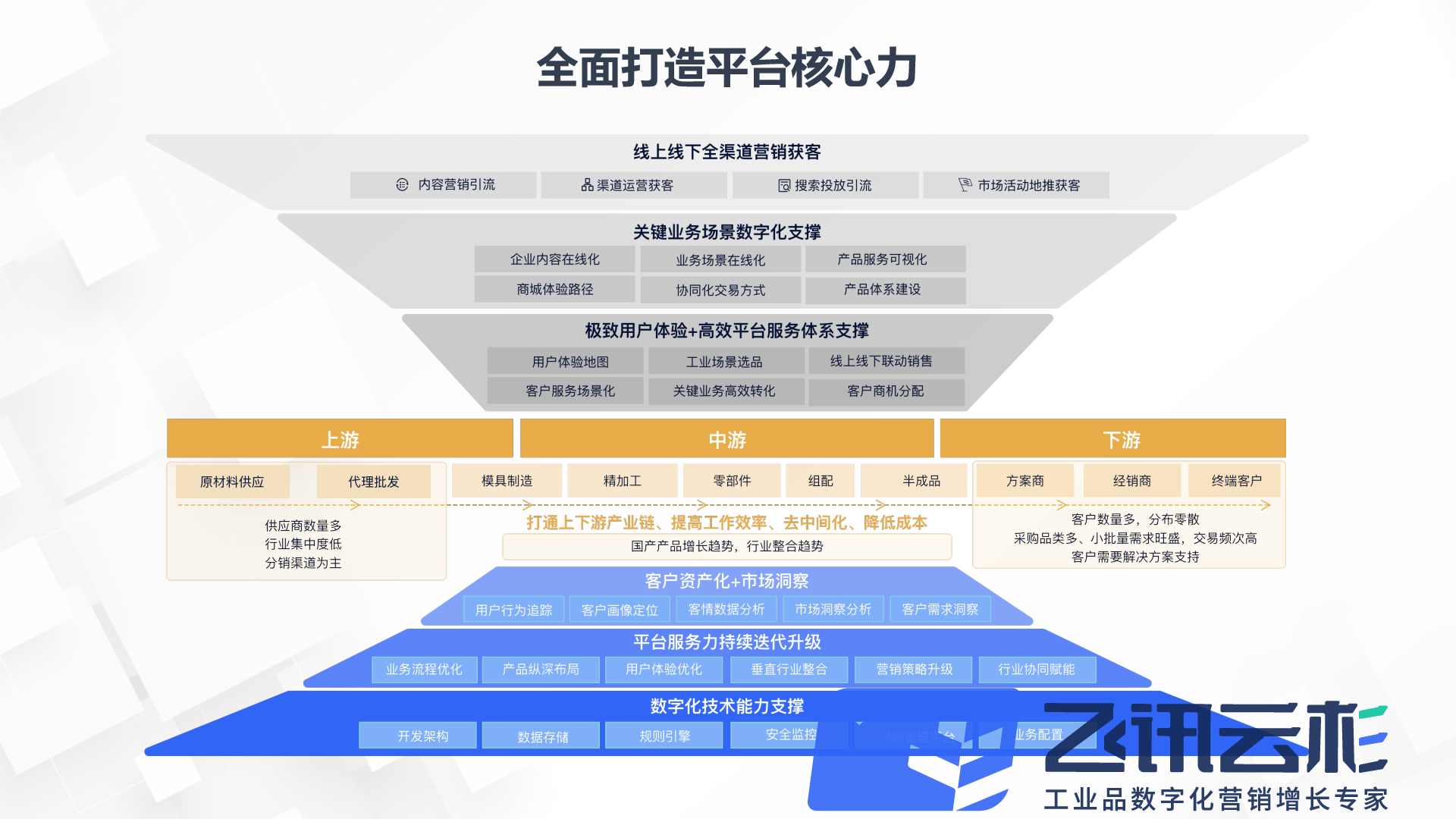

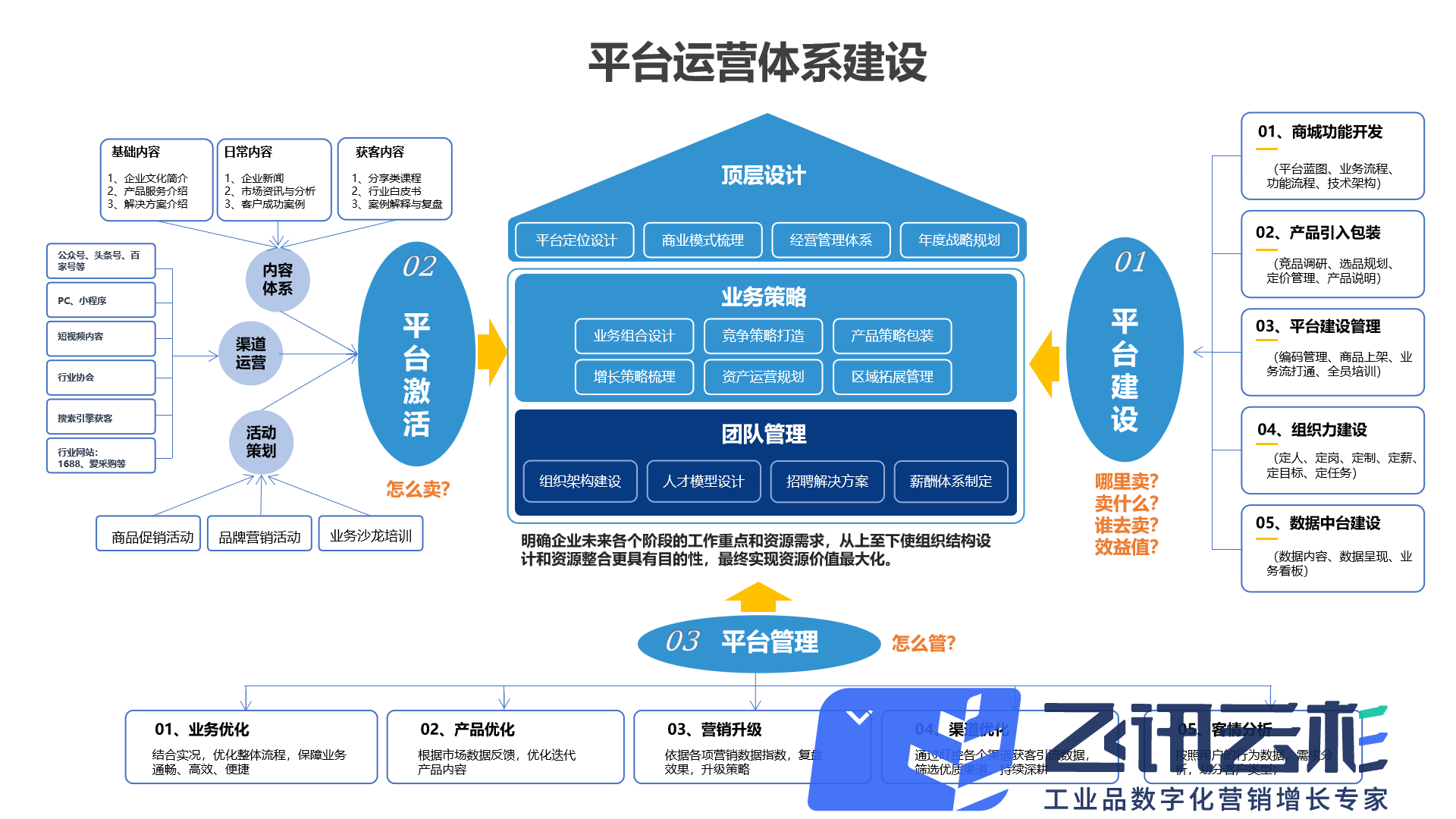

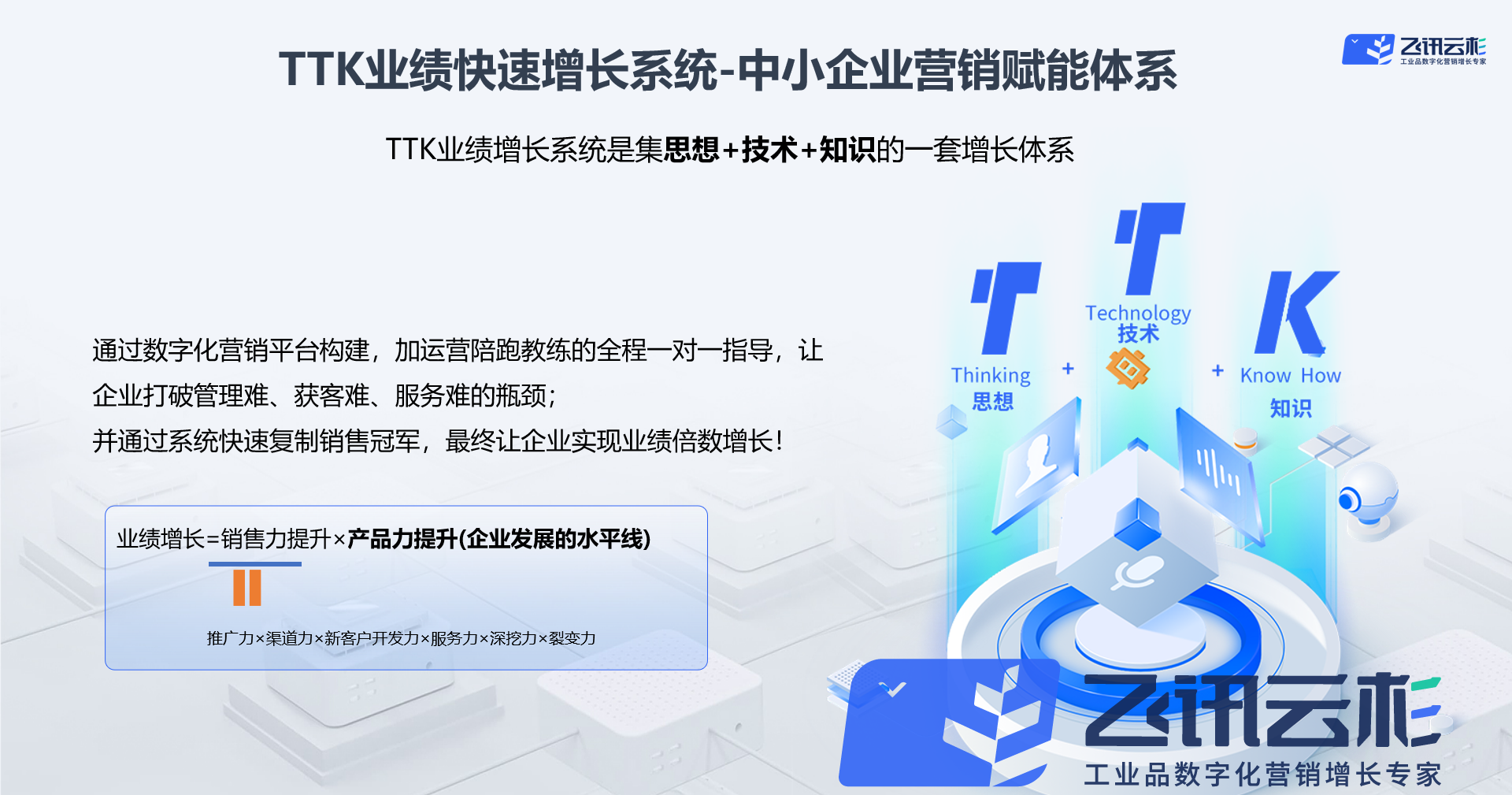

飞讯云杉是一家提供全链数字化营销解决方案的企业,聚焦产业互联网平台孵化服务,为工业制造企业搭建数字化营销-数字化供应链-业务智能决策全链数字化营销业务体系,实现工业品营销模式的创新,通过数字化赋能销售快速复制,让每一个工业品制造企业都拥有全链数字化营销业务体系。

请先 登录后发表评论 ~