工业油水分离设备产业运营平台系统搭建

Title: Building an Industrial Oil-Water Separation Equipment Industry Operations Platform System

Introduction:

In today's industrial landscape, the efficient and effective separation of oil and water has become a crucial process for various sectors. To streamline and optimize this operation, an industry operations platform system for industrial oil-water separation equipment can be developed. This article explores the key components and benefits of such a system.

I. The Need for an Industrial Oil-Water Separation Equipment Industry Operations Platform System

Industrial processes often generate a significant amount of waste liquids containing oil and water. Proper separation and treatment of these liquids are essential to protect the environment and comply with regulations. An industry operations platform system for industrial oil-water separation equipment helps improve the efficiency and effectiveness of this process.

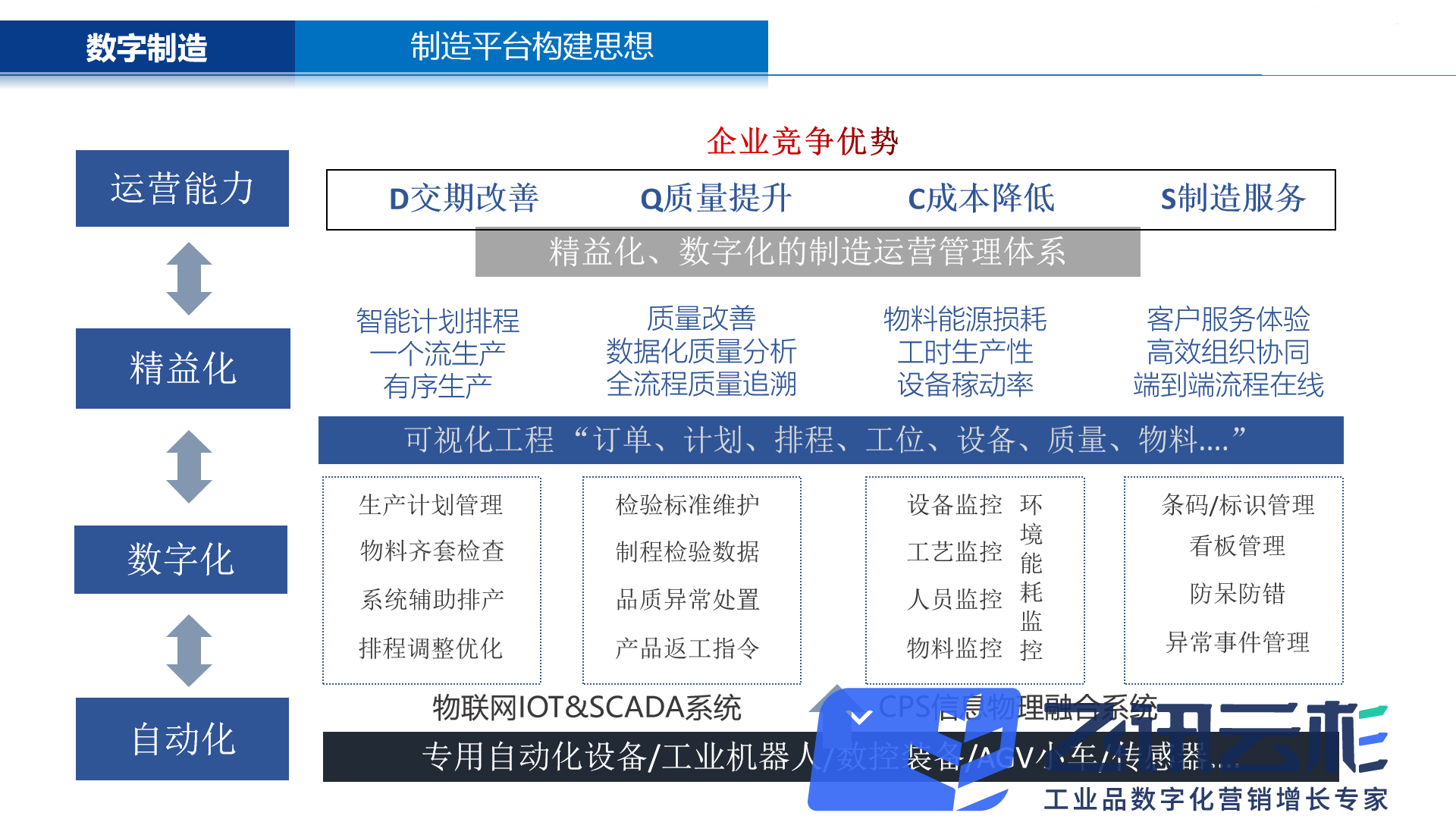

II. Components of the System

1. Data Management:

The system would incorporate a centralized database to store and manage essential information related to oil-water separation processes. This includes data on equipment specifications, operating parameters, maintenance schedules, and performance indicators. A user-friendly interface would facilitate easy access and retrieval of this data.

2. Real-time Monitoring:

The system would integrate sensors and monitoring devices to collect real-time data on operating conditions, flow rates, pressure differentials, and oil-water ratios. This information would enable operators to make informed decisions, identify potential issues, and optimize the separation process.

3. Process Automation:

By utilizing advanced automation technologies, the system can control and regulate the oil-water separation equipment. Automated features such as pump control, valve actions, and alarm systems can improve operational efficiency, reduce human error, and ensure consistent performance.

4. Analytics and Reporting:

The system would include analytical tools and algorithms to interpret the collected data, identify trends, and generate comprehensive reports. These reports would provide valuable insights into the overall performance of the separation process, allowing for continuous improvement and proactive maintenance.

III. Benefits of the Industrial Oil-Water Separation Equipment Industry Operations Platform System

1. Improved Efficiency:

By leveraging real-time monitoring and automation, the system enhances the overall efficiency of the oil-water separation process. It minimizes manual interventions, optimizes resource allocation, and reduces downtime, leading to increased productivity and cost savings.

2. Enhanced Performance:

The system's analytics and reporting capabilities enable operators to identify inefficiencies, bottlenecks, or malfunctions promptly. This empowers them to take corrective actions, fine-tune operating parameters, and optimize the equipment's performance. Consequently, the quality of separated water improves, meeting stringent regulatory standards.

3. Proactive Maintenance:

With a comprehensive database and analytical tools, the system facilitates proactive maintenance planning. It can predict potential equipment failures, schedule preventive maintenance activities, and reduce unplanned downtime. This results in longer equipment lifespan, reduced maintenance costs, and higher operational reliability.

4. Regulatory Compliance:

The system ensures that the oil-water separation equipment operates within the required environmental regulations. The accurate monitoring and reporting features enable the documentation of compliance with regulatory standards, reducing potential fines and reputational risks.

Conclusion:

The development of an industry operations platform system for industrial oil-water separation equipment brings numerous advantages to the sector. By integrating data management, real-time monitoring, process automation, and analytics, the system enhances efficiency, performance, and compliance. It represents a significant step towards sustainable and environmentally responsible industrial operations.

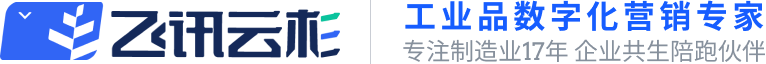

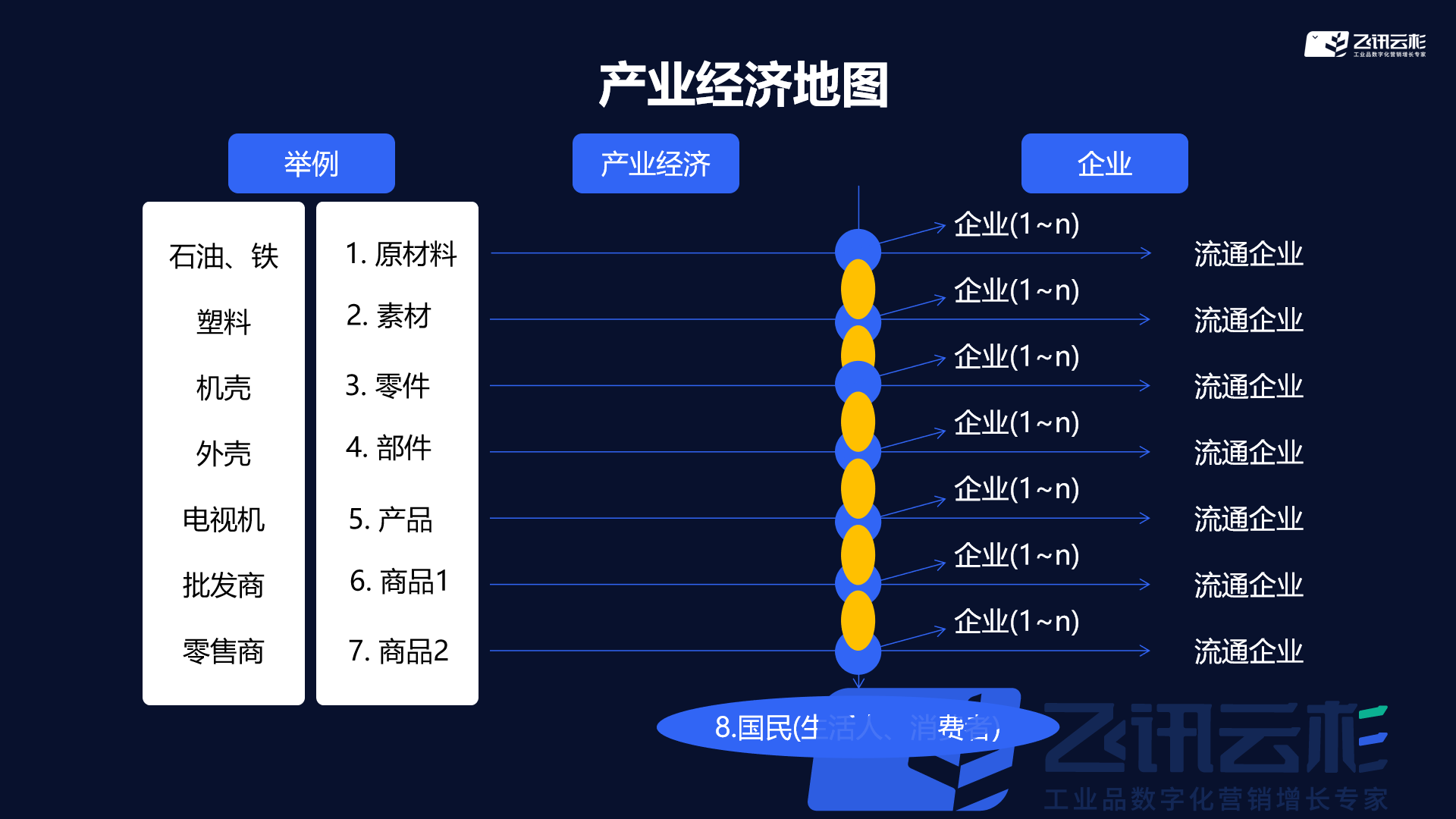

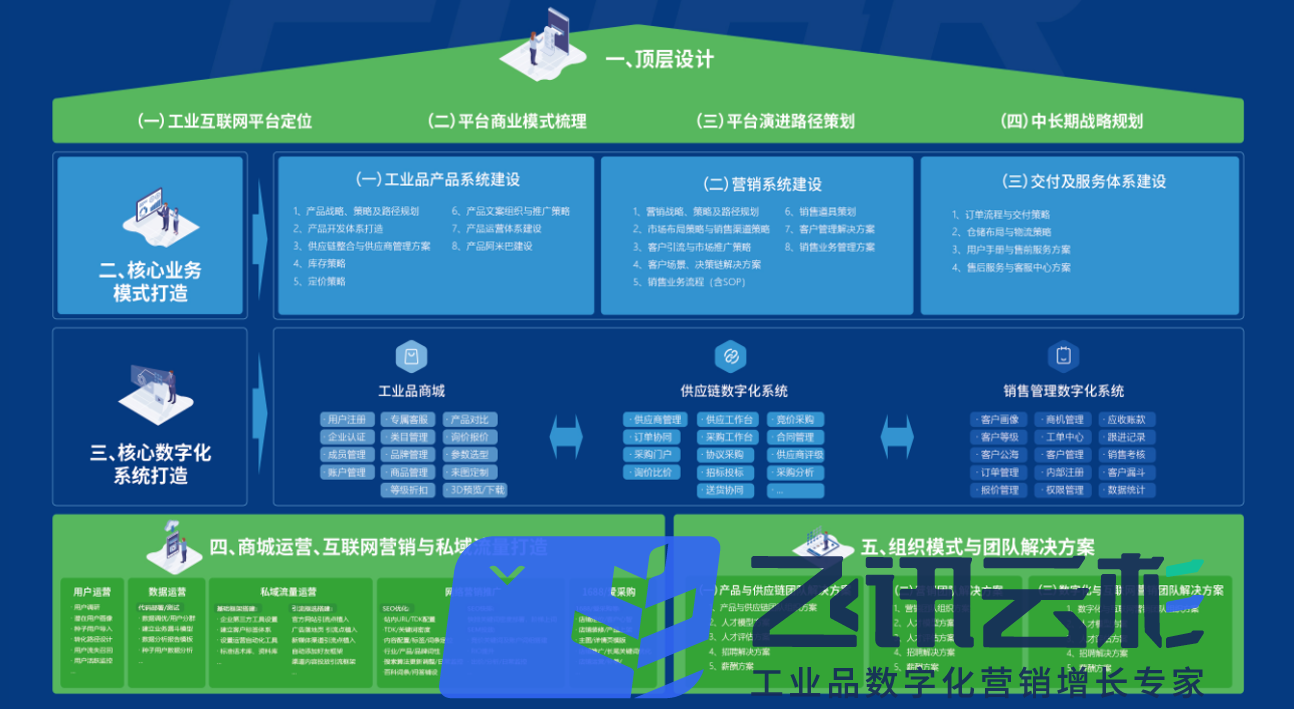

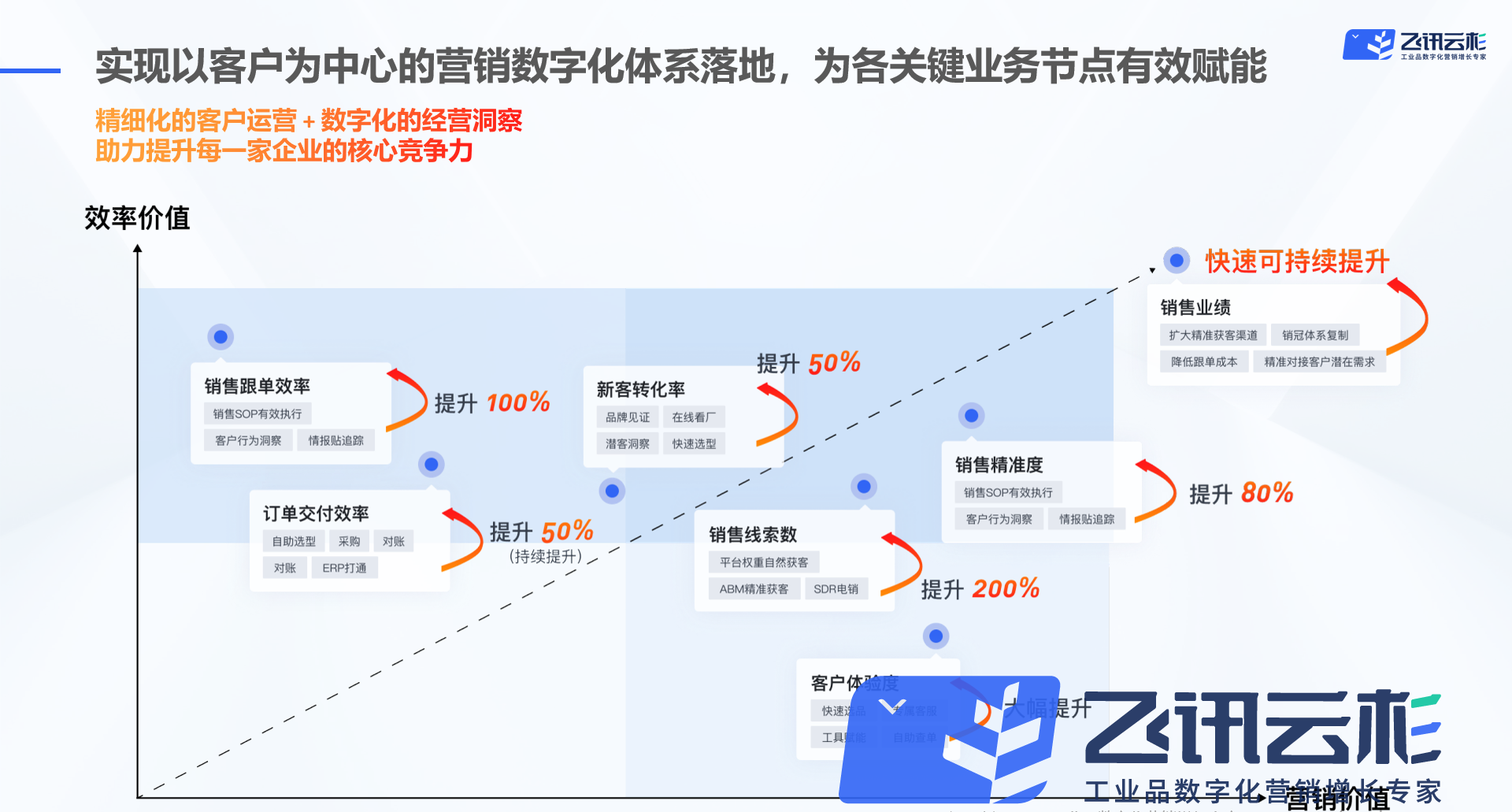

飞讯云杉是一家提供全链数字化营销解决方案的企业,聚焦产业互联网平台孵化服务,为工业制造企业搭建数字化营销-数字化供应链-业务智能决策全链数字化营销业务体系,实现工业品营销模式的创新,通过数字化赋能销售快速复制,让每一个工业品制造企业都拥有全链数字化营销业务体系。

请先 登录后发表评论 ~