机械传动件工业互联网平台搭建

Title: Building a Mechanical Transmission Component Industrial Internet Platform

Introduction:

With the rapid development of the Internet and Industry 4.0, various industries are embracing digital transformation. In the field of machinery manufacturing, the construction of an industrial internet platform plays a crucial role in improving efficiency, reducing costs, and promoting sustainable development. This article will explore the significance and key considerations in building a mechanical transmission component industrial internet platform.

1. Significance of the Industrial Internet Platform:

The mechanical transmission component industry is essential to the operation of various sectors, such as automotive, aerospace, and machinery manufacturing. Establishing an industrial internet platform for this industry facilitates the integration of information resources, enhances collaboration among enterprises, and promotes technological innovation. The platform enables real-time monitoring, data analysis, and intelligent decision-making, leading to improved production efficiency, quality control, and supply chain management.

2. Key Considerations in Platform Construction:

a) Data Integration: The successful implementation of an industrial internet platform relies on effective data integration from various sources. It is crucial to establish a standardized data format and interface to ensure seamless data transmission among different systems. This integration enables data sharing, reducing redundancy, minimizing errors, and improving overall operational efficiency.

b) Cybersecurity: As the platform connects multiple stakeholders, it is paramount to prioritize cybersecurity measures. Implementing robust security protocols, encryption techniques, and authentication procedures ensures the protection of sensitive data and prevents unauthorized access. Regular audits and updates should be conducted to address emerging threats and vulnerabilities.

c) Scalability and Flexibility: The platform should be designed with scalability and flexibility in mind. With advancements in technology and expanding business needs, the platform must accommodate future growth and changes. An agile infrastructure allows for the integration of emerging technologies such as artificial intelligence (AI), Internet of Things (IoT), and big data analytics, enhancing the platform's capabilities and competitiveness.

d) User-Friendly Interface: A user-friendly interface is essential for widespread adoption and effective utilization of the platform. The interface should be intuitive, easy to navigate, and provide comprehensive functionalities that address the specific needs of users. Clear visualizations, real-time monitoring, and customizable dashboards enhance user experience and facilitate informed decision-making.

e) Collaboration and Connectivity: The platform should promote collaboration among industry participants. Features such as online forums, discussion boards, and collaborative tools facilitate knowledge sharing, foster innovation, and enable networking opportunities. Integration with other industry platforms and systems further enhances connectivity, allowing seamless interaction between suppliers, manufacturers, and customers.

3. Benefits of the Industrial Internet Platform:

a) Operational Efficiency: By providing real-time monitoring and analysis of production processes, the platform enables proactive maintenance, reducing downtime and optimizing equipment utilization. Predictive analytics and AI algorithms help identify potential failures and inefficiencies, allowing for timely interventions and improving overall productivity.

b) Cost Reduction: The platform streamlines supply chain management, inventory control, and demand forecasting, reducing costs associated with excess inventory or stockouts. Improved efficiency in production planning and scheduling minimizes idle time and maximizes resource utilization. Also, enhanced visibility and transparency across the supply chain lead to better negotiation power and cost savings in procurement.

c) Quality Control: With data-driven insights and analytics, the platform facilitates quality control throughout the manufacturing process. Real-time data collection and analysis identify deviations and anomalies, enabling timely corrective actions and ensuring consistent product quality. This not only enhances customer satisfaction but also minimizes the risk of recalls, warranty claims, and reputational damage.

d) Sustainable Development: The platform supports sustainable practices by optimizing energy consumption, reducing waste, and promoting eco-friendly manufacturing processes. By analyzing data on energy usage, material consumption, and emissions, the platform helps identify areas for improvement, leading to resource conservation and reduced environmental impact.

Conclusion:

The construction of a mechanical transmission component industrial internet platform is crucial for advancing the efficiency, quality, and sustainability of the industry. By integrating data, promoting collaboration, and leveraging emerging technologies, the platform empowers enterprises to adapt to the digital era and seize opportunities for innovation and growth. It is an essential step towards a more connected and intelligent future in the mechanical transmission component industry.

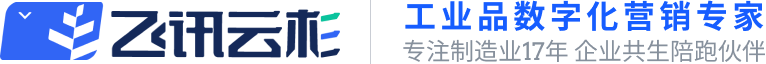

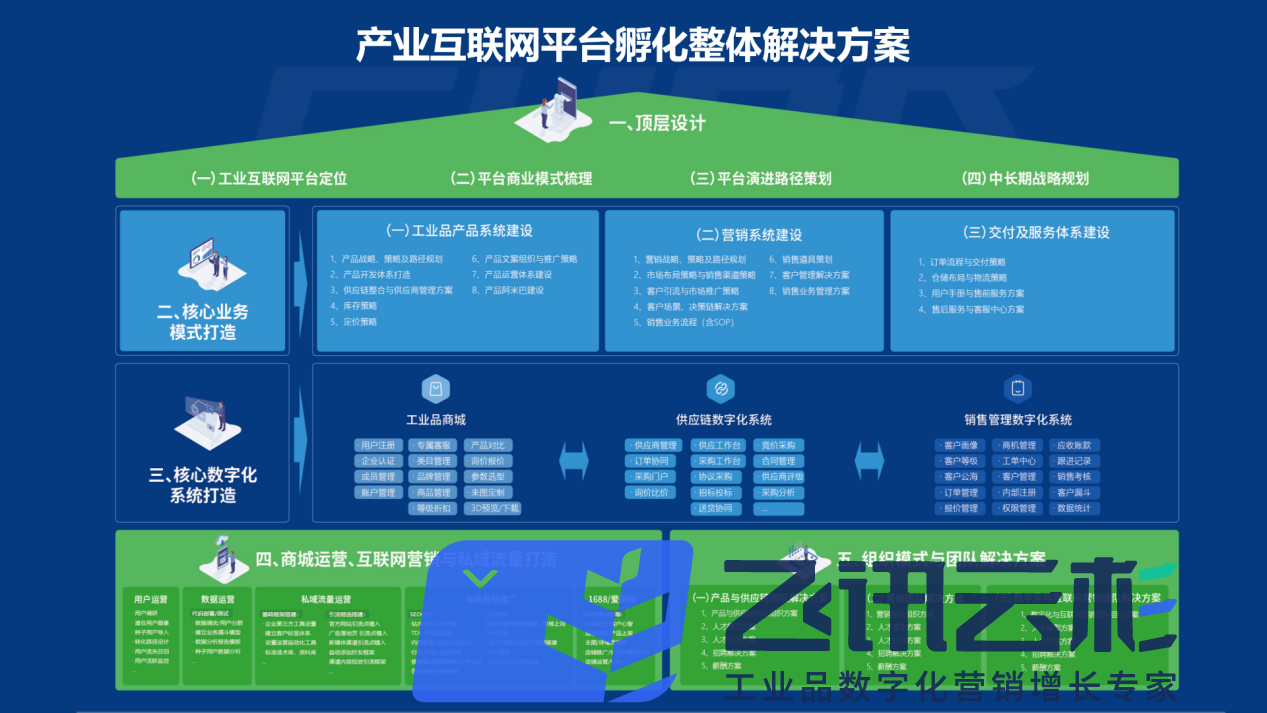

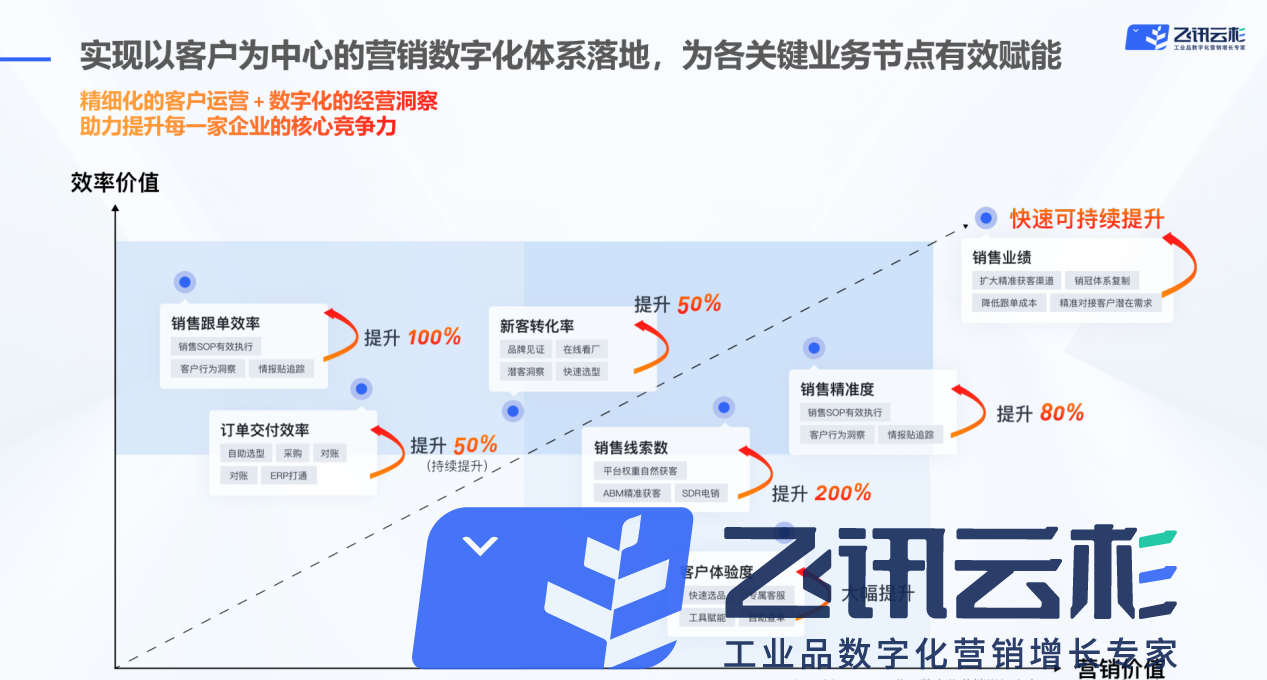

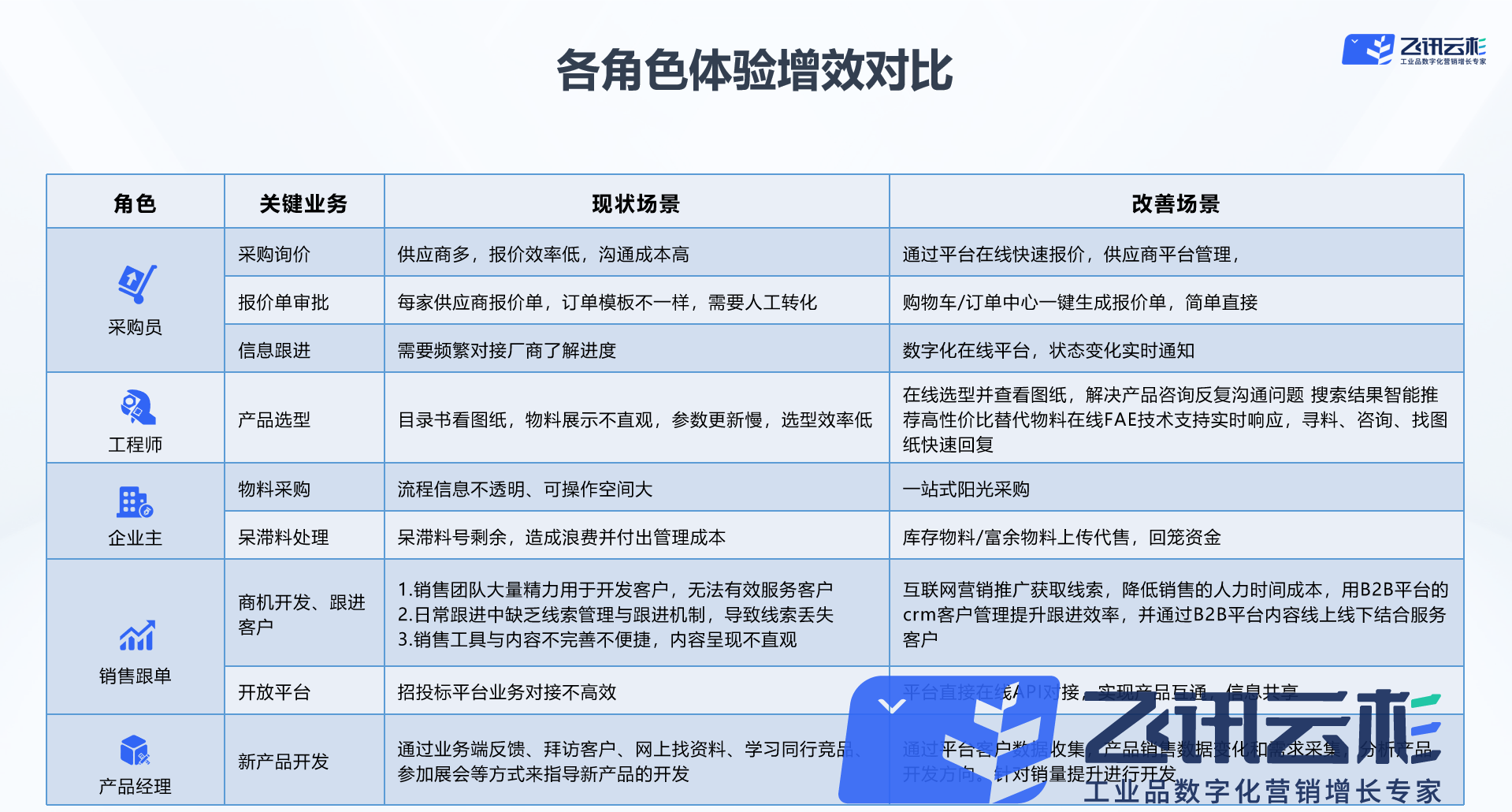

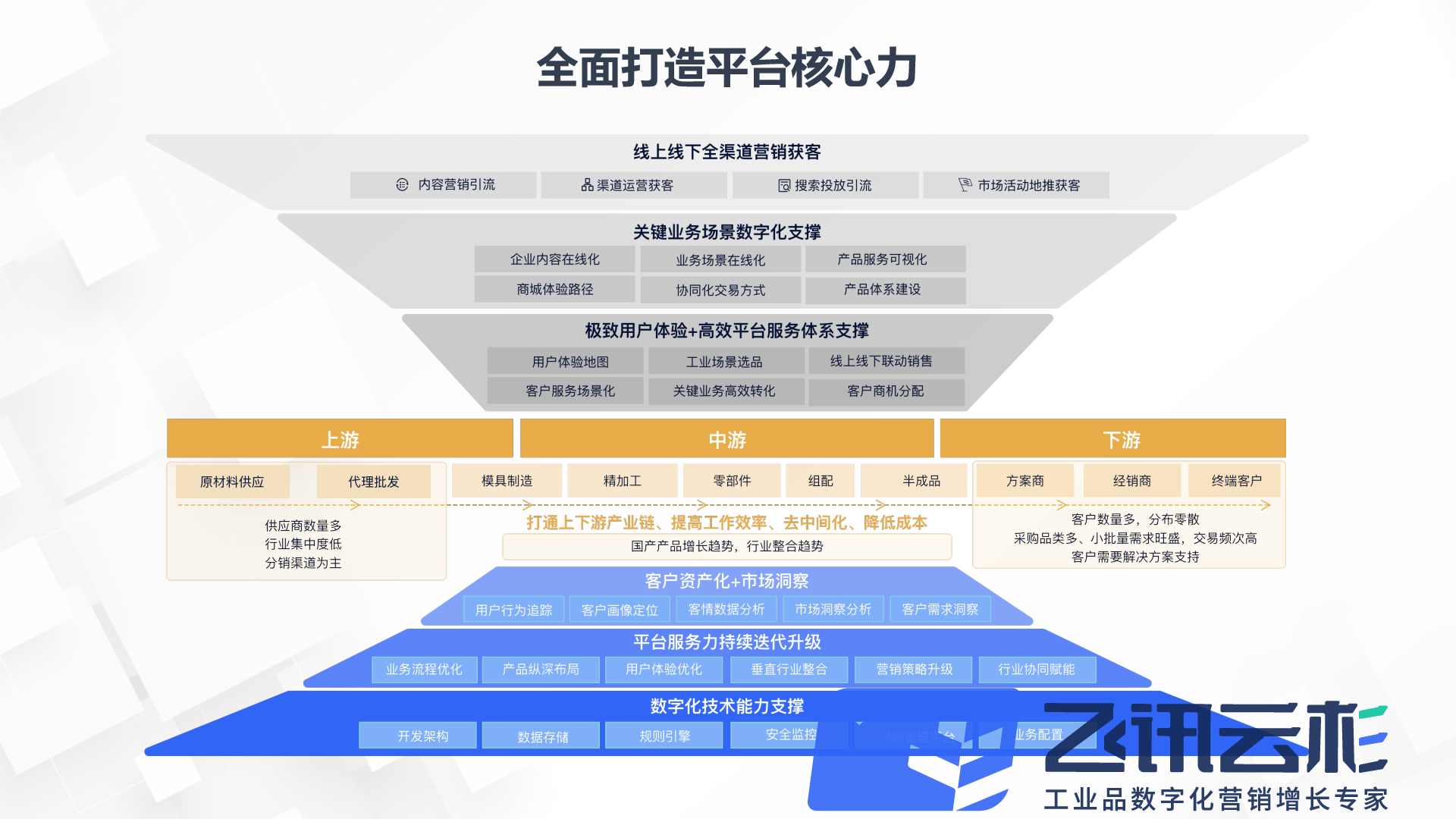

飞讯云杉是一家提供全链数字化营销解决方案的企业,聚焦产业互联网平台孵化服务,为工业制造企业搭建数字化营销-数字化供应链-业务智能决策全链数字化营销业务体系,实现工业品营销模式的创新,通过数字化赋能销售快速复制,让每一个工业品制造企业都拥有全链数字化营销业务体系。

请先 登录后发表评论 ~