焊接机器人工业互联网平台建设

Title: Building an Industrial Internet Platform for Welding Robots

Introduction:

In recent years, the rise of robotic technology has revolutionized various industries, including manufacturing. Among them, welding robots have played a crucial role in improving efficiency, quality, and safety in the welding process. To optimize the utilization of these robots, the construction of an industrial internet platform specific to welding robots is imperative. This article will discuss the significance, benefits, and key components of such a platform.

I. Significance of Building an Industrial Internet Platform for Welding Robots

The welding industry is witnessing a paradigm shift, with manual welding being gradually replaced by robotic welding. However, the full potential of these welding robots remains untapped without a comprehensive industrial internet platform. Such a platform would enable seamless integration and cooperation between robots, equipment, manufacturers, and other stakeholders, leading to increased productivity and profitability.

II. Benefits of an Industrial Internet Platform for Welding Robots

1. Centralized Management: An industrial internet platform allows for centralized management of welding robots across multiple production lines or even different factories. Through real-time monitoring, operators can track robot performance, identify bottlenecks, and allocate resources effectively, optimizing overall productivity.

2. Data Analytics: The collection and analysis of data from welding robots provide valuable insights into process efficiency, quality control, and predictive maintenance. By leveraging machine learning and artificial intelligence algorithms, the platform can identify patterns, predict failures, and suggest improvements, reducing downtime and increasing reliability.

3. Remote Control and Collaboration: With an industrial internet platform, remote control and collaboration become feasible. Experts can monitor, diagnose, and adjust welding robots in real-time from anywhere, leading to faster issue resolution and reduced travel costs. Furthermore, collaboration among engineers, technicians, and operators promotes knowledge-sharing and provides opportunities for continuous improvement.

4. Supply Chain Integration: Integrating the industrial internet platform with the supply chain enables seamless communication between manufacturers, suppliers, and customers. This integration facilitates efficient inventory management, flexible production planning, and timely response to customer demands, resulting in reduced lead times and improved customer satisfaction.

III. Key Components of an Industrial Internet Platform for Welding Robots

1. Data Collection and Analysis: The platform should have the capability to collect and store data from various sensors and devices attached to welding robots. Advanced analytics tools should be integrated to process this data, providing actionable insights and facilitating decision-making.

2. Connectivity and Communication: Effective connectivity protocols and communication channels should be established for seamless integration with welding robots, equipment, and other related systems. This ensures real-time data transmission, remote control, and collaboration capabilities.

3. Security and Privacy: As with any internet-connected system, security and privacy are paramount. Robust cybersecurity measures should be implemented to safeguard sensitive data, prevent unauthorized access, and protect against potential cyber threats.

4. User-friendly Interface: The platform should have an intuitive and user-friendly interface that allows operators, engineers, and managers to easily access and navigate through the system. Visualizations, dashboards, and customizable reports should be provided to present data and insights in a clear and concise manner.

Conclusion:

The construction of an industrial internet platform specific to welding robots represents a significant opportunity for increased efficiency, quality, and collaboration in the welding industry. With centralized management, advanced analytics, remote control capabilities, and supply chain integration, this platform will unleash the full potential of welding robots, leading to enhanced productivity and profitability for manufacturers. By embracing this technological advancement, companies can stay ahead in the competitive landscape and drive progress in the broader manufacturing sector.

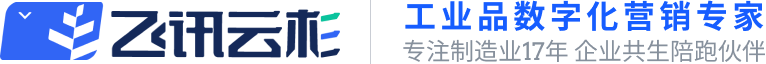

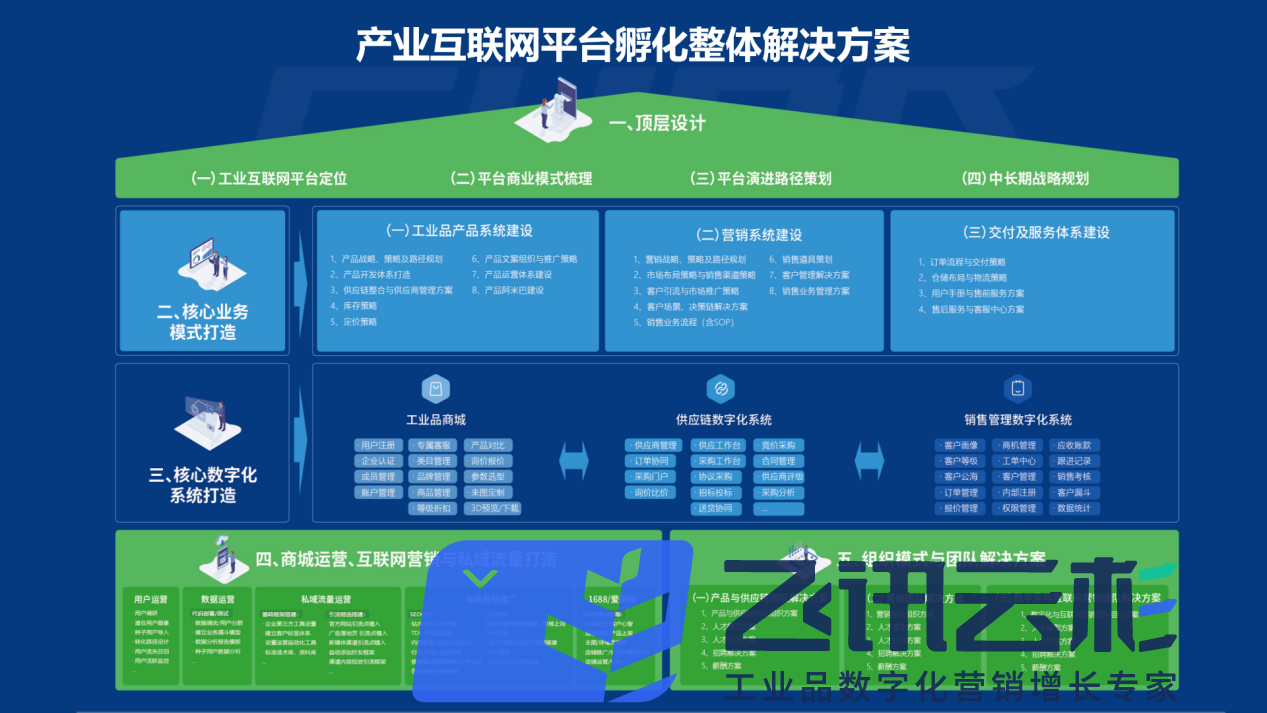

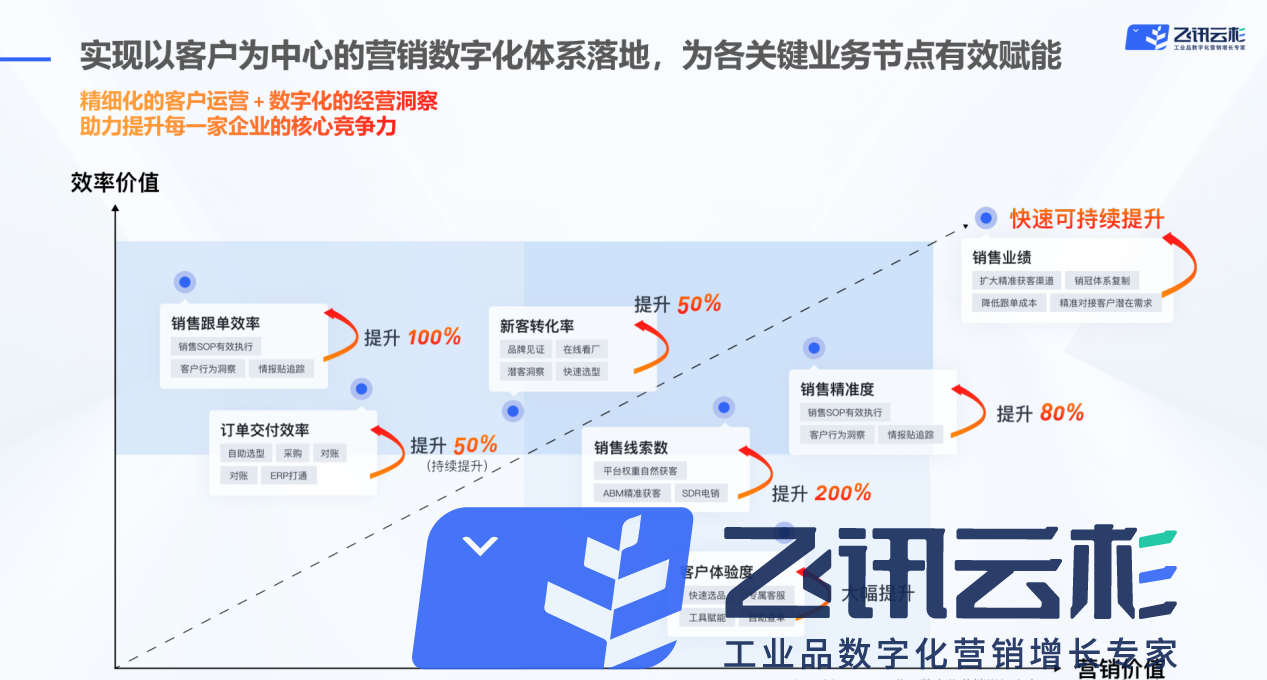

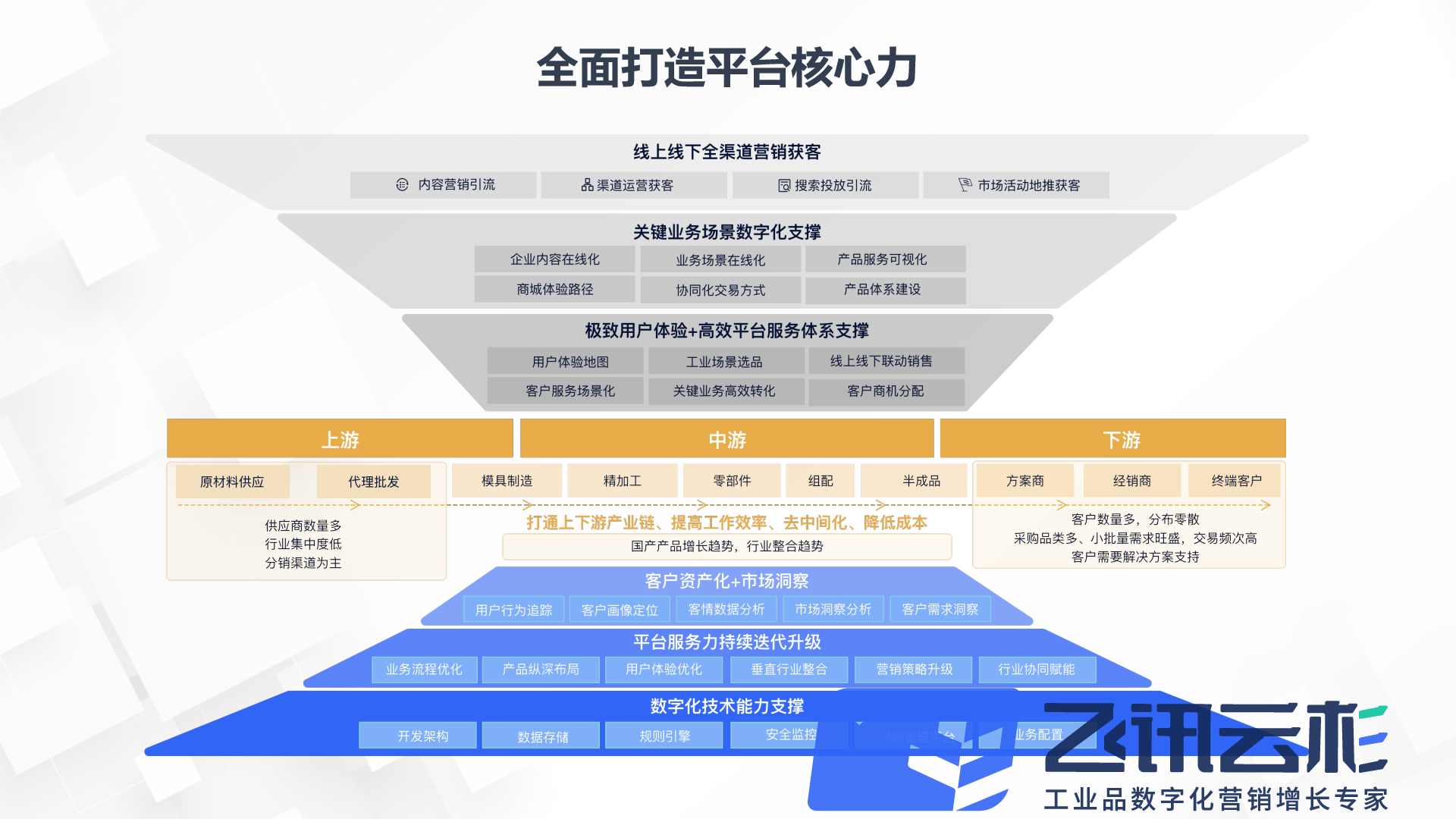

飞讯云杉是一家提供全链数字化营销解决方案的企业,聚焦产业互联网平台孵化服务,为工业制造企业搭建数字化营销-数字化供应链-业务智能决策全链数字化营销业务体系,实现工业品营销模式的创新,通过数字化赋能销售快速复制,让每一个工业品制造企业都拥有全链数字化营销业务体系。

请先 登录后发表评论 ~