压力容器产业运营平台解决方案

Title: A Solution for Operating Platforms in the Pressure Vessel Industry

Introduction:

The pressure vessel industry plays a crucial role in various sectors, including oil and gas, chemical, and power generation. As the demand for pressure vessels continues to grow, there is a need for an efficient and comprehensive operating platform. This article presents a solution that addresses the challenges faced by the pressure vessel industry, providing a streamlined approach to operations.

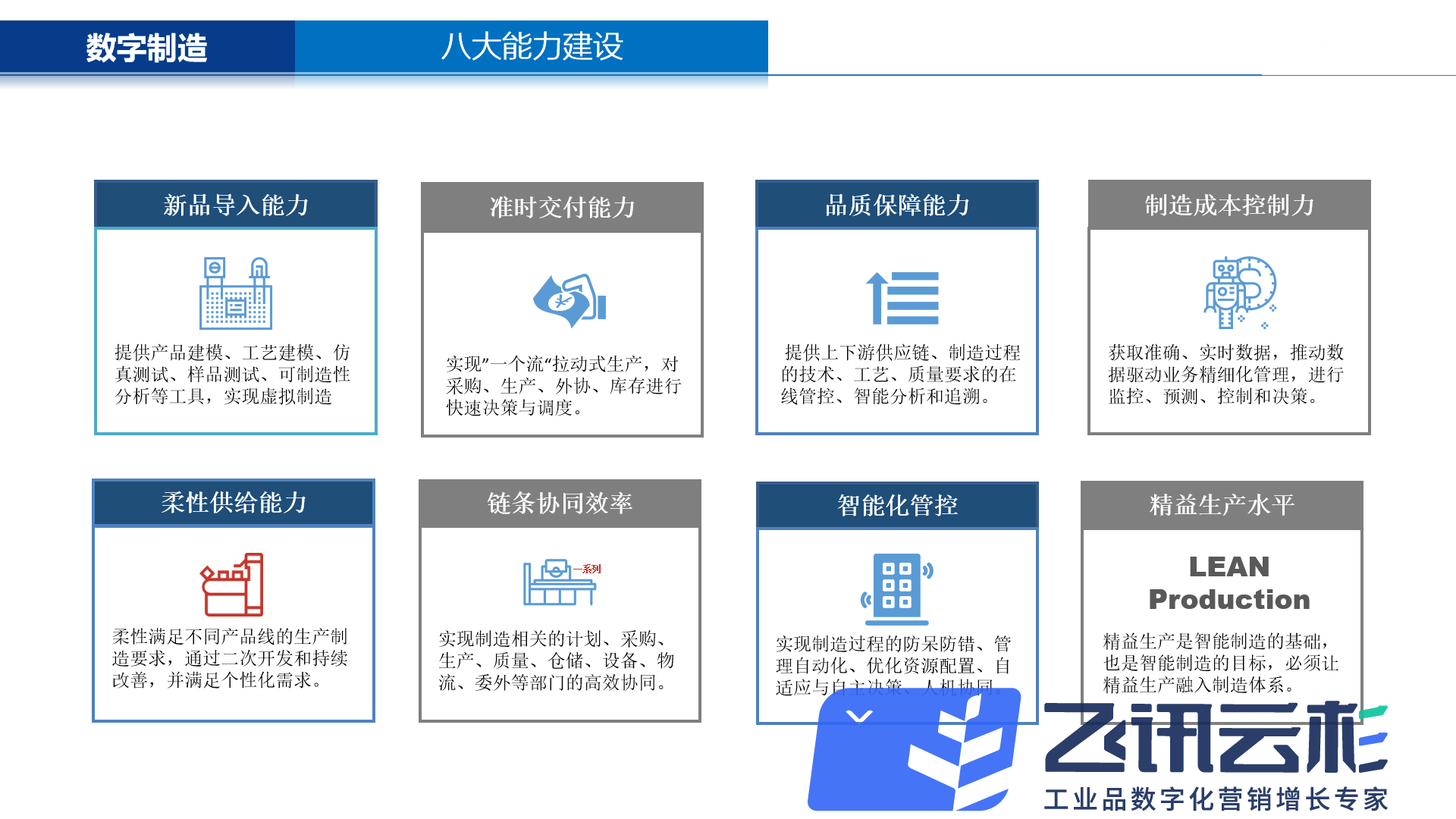

1. Streamlining Manufacturing Processes:

The operating platform aims to streamline manufacturing processes by integrating automation and digitalization. By leveraging technologies such as robotics, artificial intelligence, and the Internet of Things (IoT), manufacturers can improve efficiency and accuracy. Robots can be employed for tasks such as welding and inspection, reducing reliance on manual labor and ensuring consistent quality. Advanced analytics can optimize production schedules, inventory management, and supply chain logistics, enabling manufacturers to meet delivery deadlines effectively.

2. Enhancing Quality Control:

Quality control is of utmost importance in the pressure vessel industry, as any defects or failures can have severe consequences. The operating platform incorporates advanced inspection techniques, such as non-destructive testing (NDT) and remote monitoring. NDT techniques like ultrasonic testing and radiography can identify flaws, cracks, or material imperfections without damaging the vessel. Remote monitoring systems utilize sensors placed on pressure vessels to collect data in real-time, providing insights into performance and detecting any anomalies. This proactive approach to quality control ensures compliance with safety regulations and minimizes the risk of accidents.

3. Ensuring Regulatory Compliance:

The pressure vessel industry is subject to strict regulatory requirements to ensure the safety and integrity of the equipment. The operating platform includes a comprehensive compliance module that keeps track of relevant regulations and standards. It automatically updates manufacturers on any changes in compliance requirements and assists in generating reports and documentation. This feature relieves the burden of manual compliance monitoring and ensures that all pressure vessels produced adhere to the necessary guidelines.

4. Facilitating Communication and Collaboration:

Effective communication and collaboration are essential for successful operations in the pressure vessel industry. The operating platform provides a centralized hub where all stakeholders, including manufacturers, suppliers, engineers, and clients, can interact and share information. Through real-time messaging, document sharing, and project management tools, the platform facilitates seamless collaboration, ensuring that everyone involved is on the same page. This enhanced communication streamlines decision-making processes, reduces errors, and accelerates project completion.

5. Empowering Data-Driven Decision Making:

Data analytics plays a significant role in improving operational efficiency and informed decision making. The operating platform collects and analyzes data from various sources, including manufacturing processes, inspection records, and performance monitoring. Advanced analytics algorithms identify patterns, trends, and potential areas for improvement. Manufacturers can leverage these insights to optimize production, reduce costs, and enhance overall performance. Additionally, data-driven decision making enables predictive maintenance, reducing downtime and extending the lifespan of pressure vessels.

Conclusion:

By embracing an operating platform tailored specifically for the pressure vessel industry, manufacturers can overcome the challenges associated with operations. Streamlining manufacturing processes, enhancing quality control, ensuring regulatory compliance, facilitating communication and collaboration, and empowering data-driven decision making are key features that will revolutionize the industry. The proposed solution paves the way for a more efficient, safe, and sustainable pressure vessel industry, meeting the ever-increasing demand while maintaining high-quality standards.

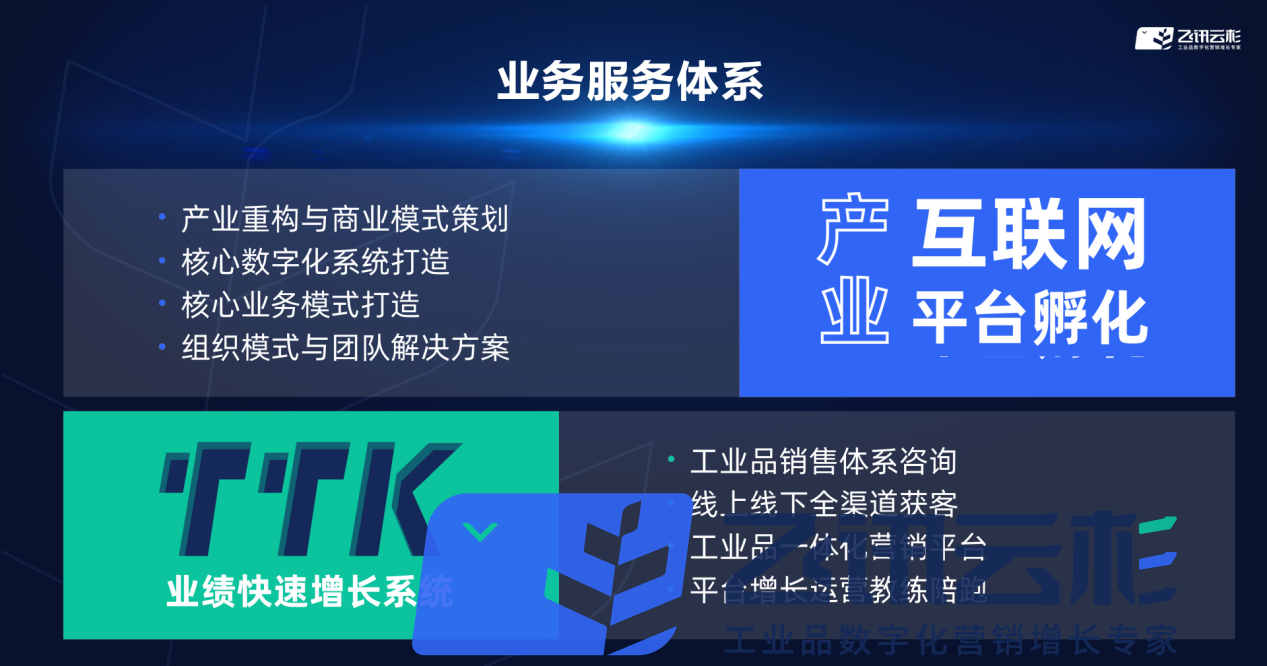

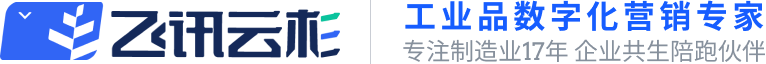

飞讯云杉是一家提供全链数字化营销解决方案的企业,聚焦产业互联网平台孵化服务,为工业制造企业搭建数字化营销-数字化供应链-业务智能决策全链数字化营销业务体系,实现工业品营销模式的创新,通过数字化赋能销售快速复制,让每一个工业品制造企业都拥有全链数字化营销业务体系。

请先 登录后发表评论 ~